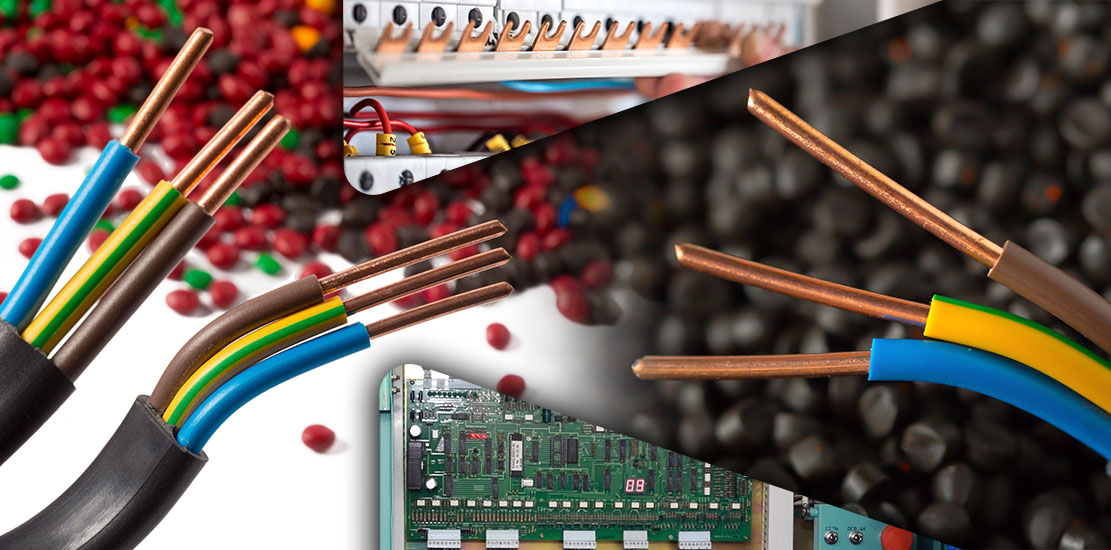

The Rising Demand for PVC Cables in Domestic wiring and Lighting

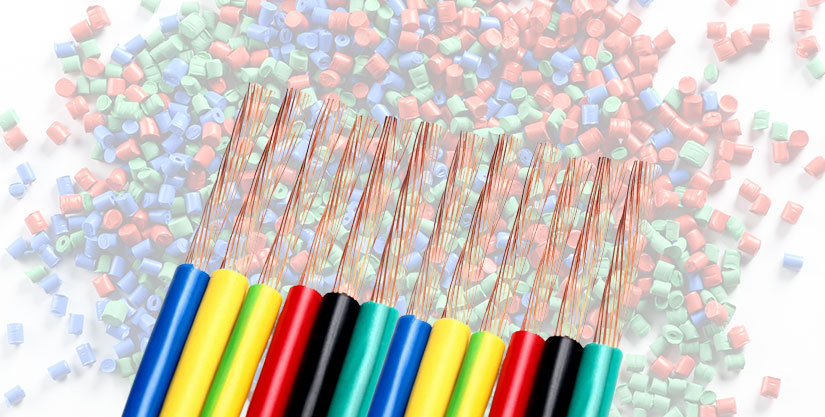

PVC wire and cables are the popular choices for household wiring these days. Polyvinyl chloride (PVC) gets widely used in electrical cables for insulation, bedding, and sheathing due to its excellent properties and ease of processing.

PVC is considered one of the versatile thermoplastics due to its flexibility. Even though, inherently, PVC is rigid and hard, when combined with additives like plasticizers, stabilizers, lubricants, and fillers, the properties of PVC enhance. It makes PVC sheathed and insulated cables suitable, flexible, and safe for many domestic and industrial applications.

Introduction of PVC for Wire and Cable Insulation

PVC got introduced as wire and cable insulation material in the 1930s and 1940s. PVC's Physical, chemical, electrical, and flame-retardant properties made it a preferred insulation material.

Gradually, with the production improvement of PVC resin, plasticizers, industrial auxiliary, and promotion and application development of new varieties, the wire and cable industry made a qualitative improvement in the cable industry.

The rising human awareness of environmental protection and concern for health and environmental issues in the 21st century led to the formulation of strict standards and regulations for the hazardous substances used in the cable industry. Further, it led to the introduction of environmental PVC cable, making it the current theme of PVC cable development.

The in-depth research on new PVC additives, such as flame retardants, smoke suppressants, etc., helped promote the various PVC-insulated cables.

The development and application of PVC materials have transformed from ordinary PVC to flame-retardant PVC, lead-free PVC, and technical-specific PVC.

Properties and Types of PVC Wires and Cables

PVC is a thermoplastic polymer, and its properties make it suitable for applications where cables get exposed to high or low temperatures or where protection against UV radiation and degradation is required. PVC's good insulating properties make it frequently used for insulation.

Electrical Properties

PVC has a good dielectric strength, reflecting its electric strength at various power frequencies or measuring the dielectric breakdown resistance under applied voltage. It helps PVC become a strong-insulating material.

Durability

PVC is resistant to weathering, chemical rotting, corrosion, shock, and abrasion. PVC insulated cables are, therefore, suitable for outdoor environments, offering long life.

Flame Retardancy

PVC products are self-extinguishing due to chlorine content.

The oxidation index of PVC is greater than 45. Antimony trioxide combined with phosphate ester plasticizers gives excellent fire performance and mechanical properties.

Mechanical and Chemical Properties

PVC as a material is abrasion-resistant, lightweight, and tough.

It is resistant to all inorganic chemicals, offering strong resistance to diluted acids, alkalis, and aliphatic hydrocarbons.

Methods to Enhance PVC Properties

PVC resin obtained from polymerization has low thermal stability and high melting viscosity. It is unstable and needs to get stabilized to process into a finished product. Several additives like heat stabilizers, UV stabilizers, plasticizers, impact modifiers, fillers, and pigments can help enhance the properties of PVC resin.

Plasticizers - Plasticizers such as Phthalates, Adipates, Trimellitate, etc., used as softening agents, enhances rheological and mechanical performance, i.e., toughness and strength of PVC products by raising the temperature.

Heat Stabilizers - PVC has low thermal stability, and stabilizers prevent polymer degradation during processing or exposure to light. When PVC gets exposed to light- vinyl compounds initiate a self-accelerating dehydrochlorination reaction, and heat stabilizers neutralize the HCI produced, enhancing the life of the polymer.

Fillers - Fillers (such as calcium carbonate, titanium dioxide, calcined clay, glass talc, etc.) help increase the polymer stiffness and strength, improve impact performance, add color, opacity, conductivity, and many more.

Other additives like processing aids, and impact modifiers, when added, enhance the mechanical and surface properties of PVC.

Types of PVC Cables

Some common types of PVC wires and cables to meet several requirements are

Special PVC Wires and Cables

Special PVC Wires and Cables

Special PVC wires and cables exhibit specific properties for wire insulation and cable sheathing. The PVC used in these wires and cables shows good electrical and mechanical characteristics compared to average ones. These cables have high flexibility and strength to meet toughness and complicated wiring or cabling requirements. The temperature range of special PVC wires and cables is -40ºC bis +70º C for fixed laying and +5ºC bis +70 °C for flexible application.

Cold Resistant PVC Cables

Cold Resistant PVC Cables

Cold-resistant wires and cables showcase excellent mechanical strength and flexibility even at sub-zero temperatures. The temperature range of these cable types is -40ºC bis +70º C for fixed laying and flexible application, -20ºC bis to +70 °C.

Heat Resistant PVC Wires and Cables

Heat Resistant PVC Wires and Cables

Heat-resistant PVC wires and cables can resist extreme temperatures up to +105°C. The insulation and sheath materials of heat-resistant PVC cables possess excellent mechanical values to suit higher temperatures. The temperature range of these cables are

Ø Fixed laying: -40ºC bis +90º CØ Flexible application: +5 ºC bis +90 °C

Ø Short time use: – bis+150 °C

Oil Resistant Wires and Cables

Oil Resistant Wires and Cables

Oil-resistant wires and cables use oil-resistant mixtures as sheath material in cables and wires as insulation. The temperature range of oil-resistant wires and cables are

Ø Fixed Laying: – 40ºC bis +70º CØ Flexible Application: +5 ºC bis +70 °C.

Advantage of Using PVC Insulated Cables in Domestic Wiring and Lighting

PVC wires and cables are preferable for home appliances, wiring of circuits, house wiring, and lighting. Apart from the domestic application, PVC-insulated cables are also applicable for mining operations, ship wiring, submarines, and other industrial and commercial purposes. Let us delve deeper into the advantages of PVC-sheathed and insulated wires and cables.

PVC cables are Flame-retardant

PVC wires and cables are flame-retardant, and PVC sheathing is self-extinguishing. Therefore, in case of a fire accident, when the source of fire gets removed, the PVC cable stops burning. These cables are also resistant to acids, alkalis, and oils.

PVC cables are Tougher with Better Di-electric Strength

PVC cables are preferable in high-specific applications as cross-linked PVC offers better temperature resistance and is tougher than XLPE cables and other ordinary cables. They also have better dielectric strength.

Easy in Installation

PVC is flexible and gets joined and welded easily into any shape. It makes PVC wires and cables available in various sizes and styles. The lightweight property of PVC makes it easy to handle.

PVC cables are Lead-free

PVC cables do not contain lead, making them less harmful to the environment during use or disposal.

PVC Cables Provide Safety

The resistance of PVC makes it suitable in sensitive environments such as the kitchen and related environments. PVC material is odorless and non-toxic, making PVC cables suitable for food-related environments like the kitchen. Also, heat, water, and chemical resistance make PVC cables fit for such environments.

Gloster Cables PVC Insulated Wires and Cables Ensures Flawless Electricity Operations in Different Environments

Gloster Cables has an extensive experience in the wires and cables field, serving various wires and cables needs of different industrial, commercial, and domestic segments. PVC wires and cables manufactured by Gloster match international standards of quality and safety. Our lead-free and fire-resistant PVC wires and cables ensure safety and flawless electricity operations in different environmental conditions.

CONTACT US