Halogen Free Flame Retardants as Wire and Cable Jacketing Compound

The use of Flame retardants is for many years, saving lives by slowing down fires or reducing their intensity. Environmental awareness and new regulations are increasing the formulation of halogen-free flame retardants (HFFR) as they are safer for individuals and the environment.

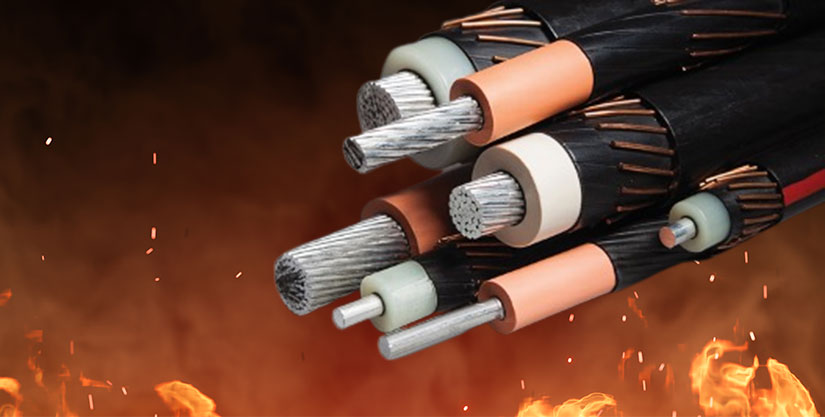

Wire and Cables with HFFR compound jacketing are critical to support the undergoing reform for a safe and efficient power supply.

The Indian cable industry collaborated with the Bureau of Indian Standards to develop IS 17048:2018, a new HFFR cable standard.

It will gradually phase out the use of PVC compound for cable jacketing. HFFR cables release fewer toxic fumes and gases when they come in contact with fire, unlike PVC wires.

Gloster Cables HFFR wires and cables promote safety, reliability, and sustainability.

Halogen Free Flame Retardants and its Classification

Flame retardants, the reactive additive added to plastics, enhance their ability to delay flames and prevent flames from spreading. These flame-retardant additives introduced to the polymer's backbone improve combustion and fire resistance and makes the product fire-safe.

Most flame retardants for plastics include halogen, a compound of chemical elements such as chlorine, bromine, and iodine. Even though halogenated flame retardants are very effective, HFFR is safer for individuals and the environment. It is non-toxic and does not release harmful gases during combustion.

HFFR usually combines phosphorous and nitrogen compounds.

We can classify HFFR into inorganic, phosphorous-based, and nitrogen-based flame retardants.

Inorganic Flame Retardants

Inorganic flame retardants mainly comprise metal hydroxides like aluminum hydroxide and magnesium hydroxide. And the use of compounds such as zinc brocade is to a small extent.

Phosphorous-based Flame Retardants

Phosphorous-based flame retardants comprise organic and inorganic phosphates, phosphonates, phosphinates, and red phosphorous. They cover a wide range of phosphorous compounds with oxidation states.

Nitrogen-based Flame Retardants

Nitrogen-based flame retardants are melamine and melamine derivatives, like melamine cyanurate, melamine polyphosphate, melem, melon, etc. They generally combine phosphorous-based flame retardants.

Application of HFFR in Cables

The wire and cable industry uses Halogen-free flame retardants or low-smoke zero halogens (LSOH) jacketing compounds. These are thermoplastic or thermoset compounds that emit less smoke when exposed to a high-heat source.

HFFR cables substitute the halogen content of the material for other non-toxic elements such as phosphorous, nitrogen, aluminum, etc. Then, they can be irradiated by electron-beam to further increase their fire and temperature resistance properties, along with mechanical strength and resilience.

Let us see some HFFRs with their corresponding polymers and their application and effectiveness.

Factors driving the growth of HFFR in Wire and Cable Industry

The HFFR market is gradually increasing and is about to reach USD 6.2 billion by 2025, according to MarketsandMarkets. THFFR or LSOH compounds usage in industrial, energy, power, and data cable designs, including coaxial and fiber optic cables, helps produce less acidic gas than halogenated compounds.

Some factors driving the growth of LSOZ or HFFR are

Safety Cable Application demand in the Construction and Defense Sector

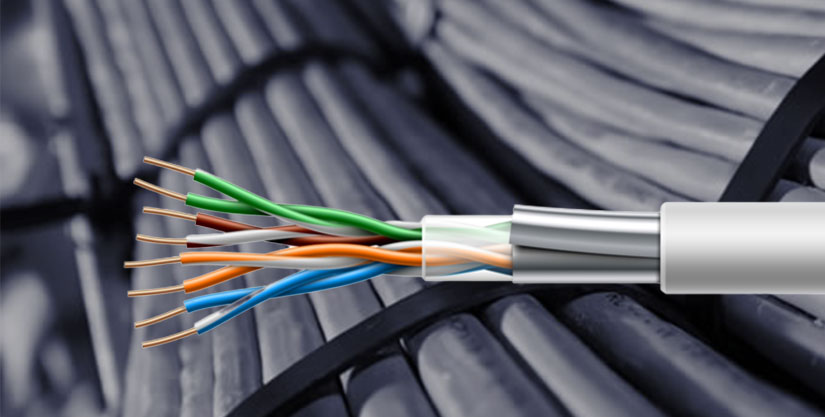

Most of the network cables, like CAT5, CAT6, etc., are insulated with PVC, polyethylene, and TPU, resulting in the release of hydrogen chloride that forms hydrochloric acid when contact with H2O. LSOH cable jacketing is custom compounded and produces minimum smoke and low toxicity when exposed to fire.

The application of HFFR cables is rising in the construction and defense sector as it meets their demand for safety with performance and reliability. In densely populated areas and enclosed public spaces, these cables provide flame resistance, low smoke production, and reduce toxic gas emissions during combustion. The major application of LSOZ cables is in mass transit, central office facilities, and residential and industrial buildings with large cable wires near people or electronic equipment.

Meet Sustainability needs along with Safety Aspects

Meet Sustainability needs along with Safety Aspects

HFFR cables are one of the safest and most eco-friendly wires that reduce energy consumption and prevent any mishap.

The low-intensity visible white smoke HFFR cables reduce the amount and density of smoke, making it easier for occupants to exit the space and increasing the safety of firefighting operations. HFFR jacketing provides high-temperature stability, better fire resistance, low toxicity, and is eco-friendly.

Stringent Action Against Halogenated Cables Driving HFFR Market

Stringent Action Against Halogenated Cables Driving HFFR Market

Halogenated flame retardants with other additives, such as antimony trioxide and zinc-based substances, are highly toxic, producing harmful gases/fumes on exposure to fire. A few brominated and chlorinated flame retardants got phased out because of environmental and health concerns.

The construction and automotive industries strictly follow fire and smoke regulations. With increasing environmental and safety concerns and environmental regulations, LS HFFR cables are gaining market growth. The growth is also due to stringent government rules against toxic flame retardants and fire safety guidelines.

High-performance Cable Variant in Hybrid and Fully Electric Vehicles

High-performance Cable Variant in Hybrid and Fully Electric Vehicles

The rise in hybrid and fully electric vehicles will increase the demand for charging cables and polymers for the interior and exterior. These charging cables must be HFFR or LSOZ for safety and performance. It will lead to an increase in HFFR or LSOZ cable demand.

New HFFR Wire and Cable Jacketing Compounds

HFFR or LSOH has limited flexibility, making it unsuitable for robotic or continuous flex operations. As a result, LSOH is in use where fire safety is of a major concern than its electrical or mechanical properties.

HFFR jackets demand a high percentage of filler material but make the jacket less chemical and water-resistant. Fillers reduce the cables' mechanical and electrical properties, and LSZH jackets may experience cracks during installation. It demands special lubricants, especially for cold regions.

Few advancements in compound materials and processing have reduced these limitations. Nanofillers in thermoplastics give advantages like lightweight, decreased gas permeability, high modulus and strength, increased solvent resistance, and increased thermal stability.

NANOFRABS, an effective halogen-free flame retardant for ABS compounds using 20 nanofillers, developed by a European Research project, is now widely used in the electrical appliances sector.

These days, zinc stearate, calcium stearate, magnesium stearate, and other lubricants like low-molecular wax are applicable in small quantities for the polyolefin and polyethylene matrix to provide flexibility to the material.

HFFR Cables Ensures Safety, Performance and Sustainability

HFFR cables provide security, safety, performance, and sustainability with their flame-retardant, less toxic, lead-free, and energy-saving properties. Gloster Cables is one of the leading wire and cable manufacturers and suppliers that provides Fire resistant, Fire survival, fire alarm, and other domestic and industrial cables with HFFR compound jacketing. At Gloster, we ensure that all our HFFR compounded Cables are safe, performing, eco-friendly, and work well with your electrical products.

CONTACT US