Instrumentation Cables: A Prerequisite for the Smooth Functioning of Industrial Processes

Process instrumentation in manufacturing and engineering industries helps measure, supervise, and control the processes. The instrumentation cables utilized in these process plants connect instruments and enable them to communicate with each other.

The introduction of computerized instrumentation in process plants demands stringent quality requirements and electrical parameters for instrumentation cables. Therefore, it has become crucial to design and manufacture instrumentation cables that can monitor and control electrical power system and their associated process in the selected process plant.

What are Instrumentation Cables

Various industries use cables for data, power, and signal transmission. Instrumentation cables help convey low-energy electric signals, utilized for observing or controlling electrical control frameworks and their related processes. These cables consist of multiple conductors, primarily used in power control and monitoring and control of electrical systems.

In process industries, where there are a lot of systems, communication of analog or digital signals, voice transmission, and signaling, the use of instrumentation cables helps in power control, monitoring and controlling of the electrical system, etc.

Instrumentation cables have an outer coating of PVC, a thermoplastic resin that makes the cable resistant to abrasion, fire, flames, and moisture. As these cables have a high amount of electromagnetic interference, they need to follow specific rules during manufacturing and installation and reduce electromagnetic interference.

Types of Instrumentation Cables

Instrumentation cables have high-standard electrical, thermal, and mechanical functions, suitable for various applications. These cables are usually categorized based on their insulation and method of shielding. The Instrumentation cable types include PVS Instrument cable, XLPE Instrument cable, Armoured cable, and Single pair and Multi pair Instrument cable.

PVS Instrument Cable

A PVC instrument cable is one of the major cables used in industry. It comprises PVC outer coating. PVC used as thermoplastic insulating materials is popular due to impeccable features such as resistivity to fire, moisture, and all type of scraps. PVC insulated cable uses copper as a conductor, which has high electrical conductivity. These cables meet several cable building standards like BS-EN-50288, UL 2250, and EIL 6-52-46.

XLPE Instrument Cable

XLPE instrument cable uses the highest quality cross-linked polyethylene material for construction. XLPE insulation has a strong 3D molecular bond structure that helps it withstand external adversity, such as exposure to UV radiation, oil, etc. XLPE cable uses a highly flexible stranded copper conductor for maximum electrical conductivity.

The cables are available in different forms of shielding, such as overall shielded pair/ triad instrument cable and individual shielded pair/triad cable.

Overall shielded Instrument Cables are twisted together and encased in a shield, foil, or mesh that helps save them from electromagnetic interference on the wire. Shielded cables require a ground for installation and have high data transfer rates.

Individual Shielded Instrument Cables have individual pairs encased in the shield. These cables help send analog signals, whereas overall shielded cables send digital signals.

Armoured Instrument Cable

Armoured instrument cables use steel/aluminum armour that offers protection mechanical protection and enables the cable to endure subjected mechanical pressure. It guards against any physical harm and vibration shock.

These cables avoid crosstalk between pairs and triads and limit noise and signal interference. The three main types of armour cables are steel wire armoured, steel wire braided, and steel tape armoured.

Single-pair and Multi-pair Instrument Cable

Single-pair and multi-pair cables are the most commonly used cables for electric signal transmission between several instruments, controllers, PLCs, DCS, etc. By twisting the single-pair or multi-pair cables, we can minimize the effect of electromagnetic interference. It also aids in reducing crosstalk between adjacent pair cables. Triad cables help connect three-wire RTDs with corresponding transmitters and temperature scanners with RTDs installed on high-capacity motors.

Technical Specification of Instrumentation Cables

A few key features of Instrumentation cables are as follows:

These cables are extremely light. Chloroprene cables are portable due to their lightweight.

The circuit implementation is easy in these cables and secure and protected.

Instrumentation cables can get installed in dry, moist, or wet environments due to PVC insulation.

These cables help transmit low-voltage data and signals and can carry up to 40 volts of signal voltage. We can use instrumentation cables to transmit electric signals in industrial control circuits and electrical installations.

Instrumentation cables are designed and manufactured following standards such as BS EN, IEC, BS, VDE, UL, DEF, and ANSI.

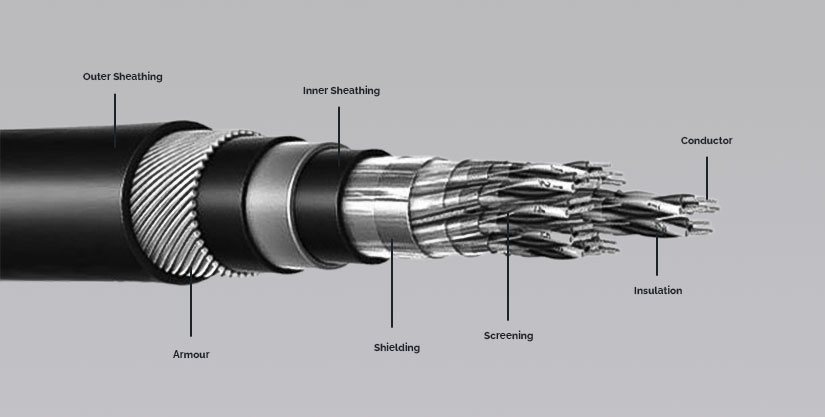

Construction of Instrumentation Cables

The construction of Instrumentation cables consists of the following parts.

Conductor - The manufacturing of Instrumentation cables includes electrolytic copper (plain or tinned) conductors in the form of solid, stranded circular, or flexible as per IS 8130, IEC 60228, and BS EN 60228 standards.

Insulation - The insulation material depends on the rated conductor temperature and electrical characteristics. For example, PVC is suitable for 70 degrees Celsius, HR PVC for 85 degrees Celsius, XLPE for 90 degrees Celsius, and Polyethylene for 70 degrees Celsius.

Screening - Twisted pairs or triads get individually shielded with Aluminium-Mylar tape with ATC Drain wire in continuous contact with the Aluminium side of the tape. Shielding of Copper tape helps provide specific requirements. For pair or triad identification, apply numbered polyester tape over each pair/triad or use number printing on the core of each pair/triad or different color coding.

Inner Sheathing - For inner sheathing, the application of extruded PVC / LSZH protects protection over the laid-up pairs or triads.

Armour - An armour gets manufactured of galvanized steel or aluminium round wire, flat strip, tape or GI, or tinned copper braiding.

Outer Sheathing - The use of extruded sheath depends on application requirements such as temperature, flame retardancy (FR), reduced smoke and acid gas emission (FRLS), and Halogen free (LSZH / ZHFR).

Shielding - For twisted pair shielding or overall shielding, use a foil shield made of 100 percent aluminium and polyester with a separate drain wire.

Application and Selection of Instrumentation Cables for Different Industries

The application of Instrumentation cables ranges from steel mills, EOT crane instrumentation and signal, and airport lighting (rated at 300/500V IS/OS) to ship instrumentation and control. Nuclear and thermal power plants use instrumentation cables with PE insulation, whereas wind power mills use EN 50288-7 instrumentation cables. For electrical machines, copper instrumentation cables with 300V PVC insulation gets used. And for turbines 300/500V IS/OS, instrument cables are available.

Selection of an instrumentation cable is challenging, especially for chemical and fertilizer industries where cables face several hazards. PVC-insulated cables are ideal for such environments. Polyvinyl chloride is a thermoplastic material generated through the polymerization process that makes PVC-insulated cables resistant to flames, repeated abrasion, weathering, corrosion, and chemicals.

The smaller diameter and stranded conductor of instrumentation cables ensure maximum flexibility and are therefore suitable where flexibility wiring is in demand. The shields of these cables help prevent electromagnetic interference.

Gloster Cables Brings Customized Instrumentation Cables for their Customers

Gloster Cables is a pioneer in the wire and cable manufacturing segment, offering a wide range of products under its product catalog. The instrumentation cables designed and manufactured by Gloster follow a stringent process, quality control, and strict adherence to national and international standards. We customize instrumentation cables based on their diverse application in various industries and customer requirements.

CONTACT US