Cable Assembly: Components and Customization

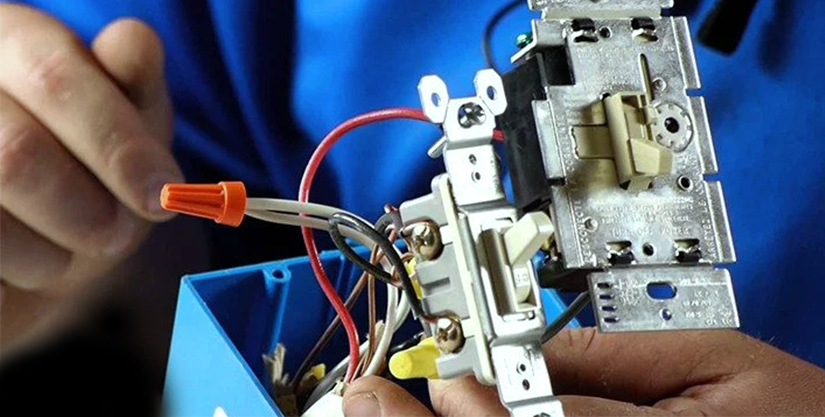

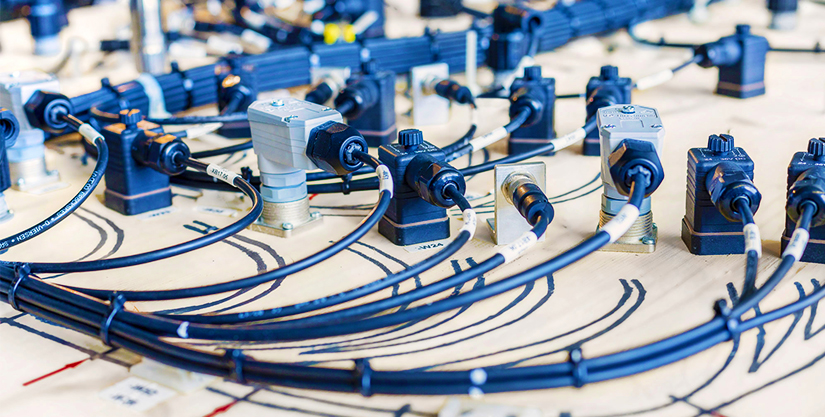

Cable assembly or wire harness assemblies are essential electrical components for home applications, original equipment manufacturers, electronic warfare, and construction industries. A cable assembly is a group of cables of different constructions, sizes, lengths, and colors housed in a single unit.

These cable assemblies serve some vital functions in easy navigation of the electrical system, keeping wiring in a highly organized configuration, avoids potential electrical hazards and other environmental damage. They are for a wide range of applications such as flat panel displays, navigation systems, shock-resistant electrical applications, in-flight entertainment systems, LED-lighted clothing, clean energy, automobile engineering, and many others.

Customized cable assemblies support specific functions in a product, with end-use applications of high standard performance. It adds safety, service life, and space optimization inside of electronics as its benefits.

Gloster Cables is one of the leading cable manufacturers and suppliers for various domestic, industrial, and commercial requirements. It brings a wide range of cable and cable assembly segments to meet customer requirements worldwide.

Factors to be Considered While Designing a Cable Assembly

Cable assembly is an essential component of an electrical system that is often ignored and addressed at the end. A cable assembly needs to get designed carefully to meet specific requirements and functions.

When designing a cable assembly or wire harness, consider the following factors.

Type of Conductor or Circuits

Type of Conductor or Circuits

The application of cable assembly helps decide the type of conductor/circuits for a cable assembly, and stranding and plating get applied to the conductive material. Before determining the size of a conductor for power usage, determine the current capacity required to hold.

Copper is one of the versatile and widely used conductors compatible with numerous coatings to avoid corrosion. Copper-clad steel and copper alloys increase the flex life and conductor's breaking strength. Cooper coated with tin retards corrosion and is used in more rigorous installations. Coating of silver or nickel makes the conductor fit for high temperatures, like 200°C and 260°C.

Stranded conductors help overcome the rigidity of solid wires, and the number and diameter of strands make the conductor more flexible.

Primary Insulation/Sheaths

Primary Insulation/Sheaths

Consider the operating temperature of the assembly, voltage level to carry, chemicals and fluids exposure, and other harsh environmental conditions before selecting insulation material. Assembly functioning in a dynamic state at extreme temperature requires rugged compound insulation. The amount of current or voltage that an assembly will carry also determines the insulation compound.

In the case of high-speed signals, the insulation gets foamed through a chemical or gas foaming process. Coloring, number printing, or stripes helps for primary insulation identification in assembly cables.

Twisting and Cabling of Conductors

Twisting and Cabling of Conductors

Twisting of wires helps reduce and cancel electromagnetic interference from external sources. In cable assemblies used for communication, the wire twisting eliminates any risk of noise or EMI impacting the assembly performance.

Cabling helically wraps conductors or twisted pairs for a more flexible assembly. It also produces a round cable assembly which is aesthetically pleasing.

Shielding

Shielding

After the cabling of conductors or pairs, overall shielding gets applied for further control of both electromagnetic interferences and radio-frequency interference. Some popular shielding is foil shield, braid shield, and spiral shield.

A foil shield is a metalized foil adhered to a polyester backing. It offers good flexibility and works well at high frequencies. The Braid shield consists of many small diameter wires braided onto the cable core using braiders. Unlike a foil shield, a braided shield is costly and provides better shielding at lower frequencies and better flex life. The spiral shield wraps small diameter wires around the cable core, providing excellent flexibility with long flex life but poor protection at high frequencies.

A foil shield is a metalized foil adhered to a polyester backing. It offers good flexibility and works well at high frequencies. The Braid shield Combining foil and braid shield provides the best protection against EMI/RFI and all frequencies.

Outer Sheath

Outer Sheath

The outer sheath is a protective covering that needs to be flame retardant to meet UL and CSA requirements and is physically strong and chemically resistant as a shield from a harsh environment. The flexibility of the outer sheath allows assembly movement during installation.

Depending on the environment assembly will get installed, types of outer sheath materials are PVC, urethane, elastomer, fluorocarbons, and non-halogen-based products. Elastomer is suitable for severe service applications, and fluorocarbon offers good fire resistance, whereas non-halogen materials are low smoky, less toxic, and less acidic.

Environmental and Regional Safety Certification

Environmental and Regional Safety Certification

The cable assembly design must follow safety regulations based on a specific region and environmental conditions. Countries like North America follow their own regulatory and safety standards, UL and CSA.

Most countries follow installation standards set by IEC, CEE, and CENELEC. REHES and RoHS directives limit set environmental standards and restrict the use of hazardous substances in products.

How to Save the Cable Assembly from Unintentional Failures

The conductors of the cable assembly get mainly used for transmitting power or data from one board or wire to another.

Cable assembly used for power transmission has to consider the type of conductor, and shielding plays a crucial role as they usually have higher current needs. .

Let us see a few factors that can save cable assembly from unintentional failures.

Voltage and Current of the System

Voltage and Current of the System

While selecting a wire to make a high-power connection, look for voltage and current requirements, wire impedance, and wire gauge. The power to get drawn from the conductor higher should be the wire gauge.

Solid Core or Stranded Wire

Solid Core or Stranded Wire

A solid core wire can handle a higher power rating but offers less flexibility and cost benefits due to less price. As there are no air gaps in the solid core, the power loss is less for long runs and can hold up in a harsh environment.

On the other hand, stranded wires offer more flexibility but at a low power rating. It is suitable for shorter cable runs in high-vibration or high-use environments.

Select a Correct Design Choice for a Proper Custom Cable Assembly

The performance, robustness, and life length of a cable assembly entirely depend on the correct design choice. A proper conductor gauge, insulation, sheathing, core, and jacket material ensure the function of cable assembly design and longevity.

Gloster Cables caters to the power and cable needs of industrial, commercial, and domestic sectors through a wide product spectrum. The product list is long, including fire survival cables, heat resistant cables, LV XLPE CABLES, Medium and HV XLPE HT cables, and triple layer FLRSH, to mention a few. Therefore, a vast exposure in cable and wire manufacturing enables Gloster Cables to manufacture a correct design Custom Cable Assembly to meet the desired requirements of its clients.

CONTACT US