The Application of Aerial Bunched Cables for Overhead Power Distribution

The traditional practice of using bare neutral conductors for overhead power lines has the drawbacks of short circuits, conductor clashing, heavy maintenance, and safety concerns. Aerial bunched cables (ABC) as a replacement to overhead power lines provide safety, reliability, less maintenance, easy installation, immunity to short circuits, and many more.

Aerial bunched cables are one of the best options for power distribution in congested urban areas, hilly terrains, and narrow lanes, where overhead lines or underground wiring is not feasible and safe. The flexibility of rerouting has eventually increased the demand for aerial bunched cables.

Description of ABC Cables and its Type

Aerial bunched cables are overhead power lines that use several insulated phase conductors bundled together tightly with a bare neutral conductor. These cables follow the same principle as overhead power lines. But the conductors in these cables are close without any air gaps, and each conductor has an insulating layer.

In contrast to traditional practices of using uninsulated conductors separated by air gaps and external forces causing a short circuit, ABC simultaneously disconnects all the conductors to avoid a short circuit.

Aerial bunched cables are considered best for over-crowded or congested areas. They provide more safety, reliability, and fewer power losses compared to conventional bare conductor overhead distribution systems.

ABC is available in different voltages with different sizes.

Low Voltage Aerial Bundle Cables

Low Voltage Aerial Bundle Cables

Low Voltage ABC can bear bare pressure of 1Kv and below and work well for overhead power lines and room entrances. LV-ABC uses aluminium and copper or aluminium alloy as conductors. These cables follow standards such as IEC 61089, BS 7870, DIN 48201, ASTM B399, BS EN50183, and NFC33-209. The maintenance cost, installation, and operating costs of these cables are low.

Medium Voltage Aerial Bundle Cables

Medium Voltage Aerial Bundle Cables

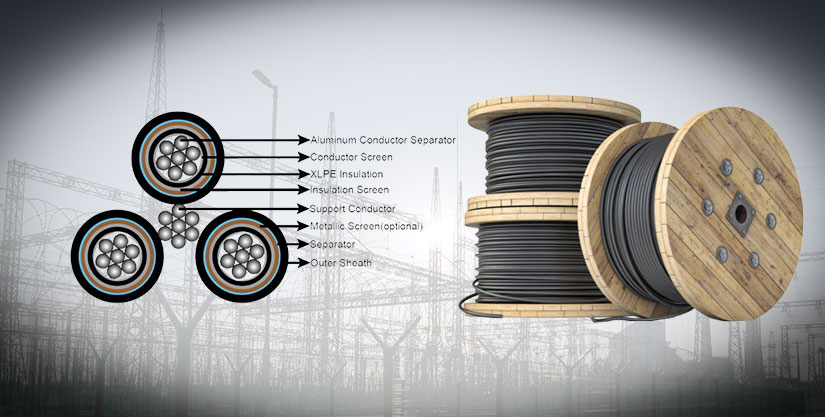

Medium voltage ABC can bare voltage levels of 10kv and below, 6.35/11kv, 12,7/22 kV, 19/33kv, etc. The conductor in MV-ABC is aluminum in a circular shape with XLPE insulation. And the inner and outer semiconductor material is compound, and the bedding material is semi-conducting. The screen has copper tape or wire, and the outer sheath is HDPE. The standard medium-voltage aerial bundled cables come in IEC60502, NF C33-209, GB 12527-90 ASTM. These cables are more suitable for power-grid transformation in urban, forest, and coastal areas.

Duplex or Triplex Service Drop Wire

Duplex or Triplex Service Drop Wire

The duplex/triplex service drop wire has a high tensile strength that can carry a load of 120V for overhead power application. These wires use PVC or XLPE insulation, and their main composition is 1350-H19 aluminum with phase conductors twisted concentrically. The neutral core gets made of AAC, ACSR, or 6201 aluminum alloy. The conductor temperature of XLPE insulation does not exceed 90 degrees Celsius, and PVC insulation is not more than 75 degrees Celsius. And these wires come in ASTM B230, B231, B232, and B-399, B498, ICEA S-76-474. Duplex wires are preferable for street lighting, outdoor lighting, and temporary services.

Construction and Material Requirement of ABC

For the aerial bunched cable construction, the XLPE and HDPE insulated conductors of aluminum together are laid and twisted around a high tensile stranded and galvanized steel insulated or bare messenger wire. We can use neutral conductors and street lighting conductors if required. Then, the assembly can get directly strung onto distribution poles or towers using standard hard wares. It required special attention in the case of HT ABC while rendering the messenger wire insulated from earthing at any distribution point.

The XLPE insulation is black. XLPE is cross-linkable low-density polyethylene made thermoset by formation from the base polymer of thermoplastic low-density polyethylene. It stabilizes XLPE insulation against any deterioration- when exposed to direct sunlight and UV radiation. It combines the best electrical properties of LDPE and superior thermo- mechanical properties.

Materials Requirement for ABC

The aluminum conductors should confirm to IS:8130 (Class-II).

The stranded high tensile galvanized steel messenger wire should be of IS:398 (Part-2) standard. And Aluminium alloy messenger should confirm to IS:398 (Part-IV).

Aerial bunched cables XLPE and HDPE insulation of power conductors must follow IS 7098 (Part I &II) and IS 6474, respectively.

The use of messenger wire reduces the tension from the current-carrying conductor, and the operating temperature of the conductor rises to 90 degrees Celsius as against 75 degrees Celsius of the bare conductor of the same size. It allows aerial bunched wires to carry an equal amount of current to that of a bare conductor of the same size.

Technical Specification of ABC Cables

Aerial bunched cables are preferable for L.T. overhead lines than conventional L.T. overhead lines with bare conductors due to less frequent faults, more safety, and no use of insulators and hardware required for bare conductors.

Let us see the technical specification of aerial bunched cable- XLPE insulated L.T cable for working voltage up to 1100 volts.

Conductor

The aluminum conductor for phase or street lightning conductors shall be H2 or H4 grade aluminum, complying with IS-8130-1984 requirements. For messenger wire, stranded All Aluminum Conductors shall be heat treated Aluminum Magnesium-Silicon Alloy Wires conforming to IS-398 (Part-IV)/1984.

Insulation

Insulation

The conductor shall be XLPE insulated and applied by extrusion conforming to standard specification IS 14255/95. The average thickness of insulation shall not be less than the standard value specified in the relevant clause. The upper insulation surface should be UV ray-resistant color, i.e., black.

Core Identification

Core Identification

The phase conductor should get insulated with black weather-resistant and XLPE suitable for 1100-volt insulation. It should have one, two, and three ridges for easy and quick identification. Then, assemble the individual cores around the insulated messenger wire. And the insulated messenger wire should have four ridges, as per IS 14255:1995.

Messenger cum Neutral Wire

Messenger cum Neutral Wire

Use aluminum alloy for making insulated messenger wire, conforming to IS 398 (Part-IV)/1994. It should have a smooth round surface to avoid damage to the other insulating sheath of the phase conductor twisted around.

Laying Up

Laying Up

To form the aerial bunched cable, twist the three power cores having ridges one, two, and three and one street lightning over the insulated messenger wire with the right-hand direction of lay. The lay ratio should comply with IS:14255/ 1995.

Advantage of Using Aerial Bunched Cables for Overhead Power Distribution

Aerial bunched cable is a better replacement for bare lines used in rural areas, in-woods and other localities, narrow streets, etc. ABC is preferred for overhead power transmission because of the following reasons.

Application of ABC provides relative immunity to short circuits due to external forces, fallen like wind, fallen-tree branches, etc. These cables can safely stand near trees and buildings.

Erection and stringing are easy with ABC. It provides hassle-free installation, as crossbars and insulations are not necessary.

ABC is reliable where the power supply is of prime importance. They provide high stability of supply voltage.

In hilly areas where the cost of erection of overhead lines or underground wires is very costly, aerial bunched cables are the best option.

Aerial Bunched Cables by Gloster Cables Ensures Safety, Reliability, and Performance

Gloster Cables is a leading wire and cable manufacturing and supplying industry, catering to several power utilities across the country. Gloster manufactures LV and MV aerial bunched wires with XLPE and HDPE insulation of different sizes to meet several overhead power transmission requirements. By following stringent quality control and standard adherence, Gloster ensures the safety, reliability, and performance efficiency of manufactured aerial bunched cables.

CONTACT US