The Use of Solid Wires and Stranded Wires for Different Home Applications

Solid and stranded wires are frequently used across electrical equipment such as cable assemblies and wire harnesses. Each has a distinct advantage based on its application and environmental conditions. The selection of these wires depends on their amperage load, use case, costs, metal type, and wire gauge.

Solid wires can carry high currents through building infrastructure, vehicle controls, and various outdoor applications. The flexibility of stranded wires makes them suitable for indoor applications such as circuit boards, connecting electronic components in cramped spaces, etc.

Introduction to Solid Wires and Stranded Wires

Solid Wires

Solid Wires

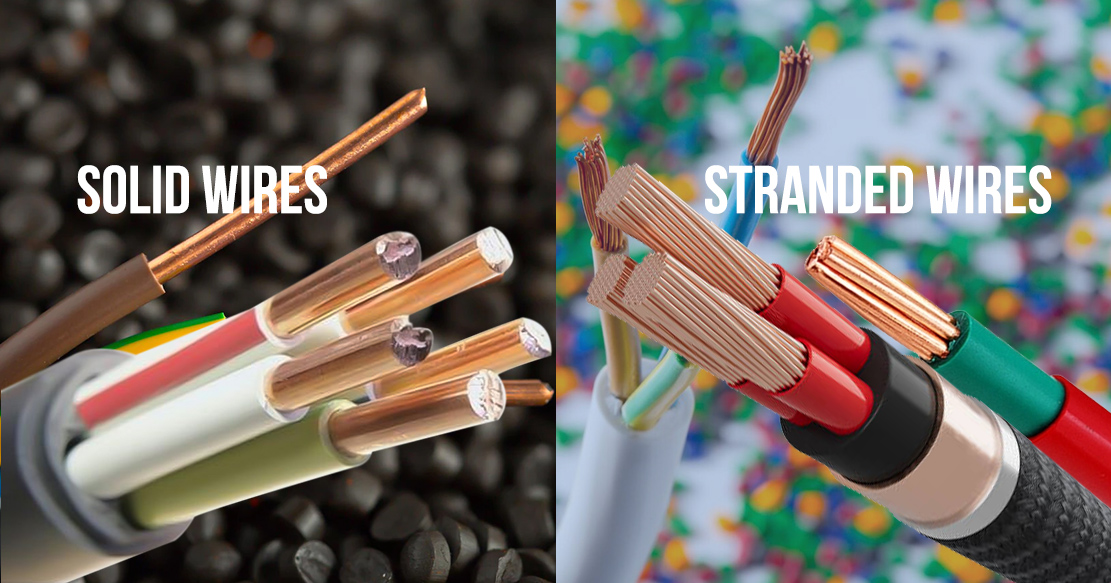

Solid wires consist of a single metal core, using one solid copper wire per conductor. These wires are usually referred to as busbars and are heavier and thicker. Copper and aluminum are the most common conductor materials used for these wires. The use of copper favors conductivity and aluminum for cost-effectiveness and large-scale installations. With the continuous advancement in material science, solid wires are gaining importance in electronics and electrical engineering. These cables offer low signal loss and affordability.

Stranded Wires

Stranded Wires

Stranded wires are thin bundled wires compressed and insulated with non-conductive materials. Here, each conductor consists of several thinner wires twisted into a bundle. These wires are made from copper due to their tensile strength, electrical conductivity, ability to resist corrosion and creep, durability, longevity, ease of installation, and solder to its thermal conductivity. Stranded wires are more flexible and reliable due to several strands. Even if one strand is cut or damaged, the wire remains intact.

How Solid Wires Differs from Stranded Wires

The single-core nature of solid wire makes it much simpler to manufacture, whereas stranded wires require more complex manufacturing processes to twist the thinner wires together. The construction and material properties of solid wires and stranded wires make them different from each other. The key differentiators of solid and stranded wire are as follows.

Flexibility

Flexibility

The stranded wires construction with several strands gives it more flexibility than solid wires. Stranded cables can withstand more bending, but those flexible strands can break or become loose over time. Solid cable is more rigid and can break if flexed more frequently, but solid conductors will hold their shape over time. It will seat properly with insulation displacement connectors on jacks, patch panels, and connecting blocks.

Current Carrying Capacity

Current Carrying Capacity

Solid cables have higher current carrying capacity than stranded ones. Solid wires are thicker, offering lower surface area for dissipation-whereas thinner wires in stranded wires contain air gaps and greater surface area with the individual strands, translating to more dissipation.

Voltage Drop

Voltage Drop

Solid wires offer less resistance, which leads to less voltage drop. In stranded wires, the voltage drop is more.

Resistance and Corrosion

Resistance and Corrosion

The electrical resistance of solid wires is less, and they are anti-corrosive in indoor and outdoor applications. Stranded wires offer comparatively higher electrical resistance. There are higher chances of corrosion of stranded wires when used in outdoor applications.

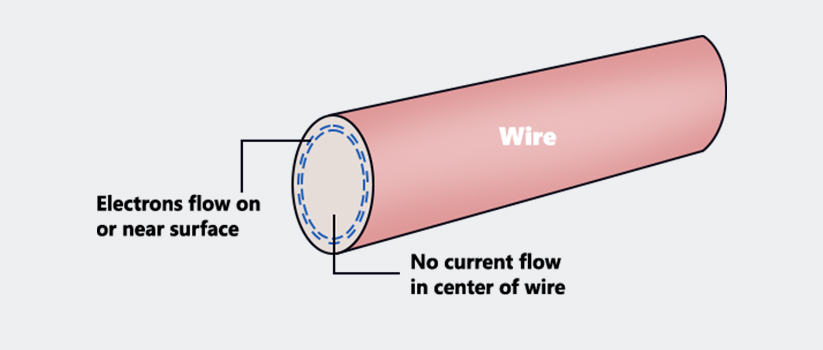

Skin Effect

Skin Effect

The use of solid wire in high-power and high-voltage transmission lines leads to a skin effect. Skin effect restricts the flow of alternating current to the surface of a conductor as an alternating magnetic field gets generated within the conductor due to current. The stranded wires have less skin effect when used in high-power transmission lines.

Transmission in High Frequencies

Transmission in High Frequencies

Solid wires have good transmission performance with high frequencies compared to stranded wires. The large wire diameters of solid cables lead to lower DC resistance by solid conductors and lower susceptibility to high-frequency effects. They support long-distance transmission and higher data rates compared with stranded cables.

Noise and Proximity Effect

Noise and Proximity Effect

The low attenuation of solid cables produces less noise. Stranded wires produce more noise with an attenuation of 20% to 50%. Solid wires have high proximity effects, but stranded wires minimize them.

Termination and Connection

Termination and Connection

The termination and connection of solid wires are easy and perfect. But stranded wires are complex in case of termination and connection.

Suitability

Suitability

Solid wires are highly suitable for long-distance power transfer because of the low-voltage drop. We can use stranded wires for comparatively short-distance applications.

Different Application of Solid wires and Stranded Wires

Solid and stranded wires' design and structure ensure their suitability for different applications.

Preferable Applications of Solid Wires

Preferable Applications of Solid Wires

The design of solid conductor cable supports the backbone and horizontal cable runs. These cables are preferable for longer distances, offering superior electrical performance and stable high frequency. We can install solid cables for outdoor applications where high current capacity and more durability are required, such as in building infrastructure. We can also install them on walls, up through the ceiling, or between work areas on the same floor.

Preferable Applications of Stranded Wires

Preferable Applications of Stranded Wires

Stranded cables are suitable for short runs as they have higher attenuation. We can use these cables between network interface cards and wall plates or between concentrators and patch panels, hubs, and other rack-mounted equipment. Stranded cables can get installed where flexibility is required, such as in circuit boards, electronic devices, etc. The flexibility of stranded cables makes them suitable for complex spaces and indoor applications.

Selection of Solid Wires and Stranded as Power Cables

The selection of solid wires and stranded wires depends on various factors such as wire gauge and length, wire flexibility, insulation type, and wire color.

The wire gauge of solid wire measures its diameter. Smaller gauge numbers correspond to thicker wires and vice versa. The choice of wire gauge should be a balance of cost, the amount of current to get carried, and the allowable voltage drop across the wire. Solid wire is the suitable option when we desire longevity, simplicity, smoothness, and cost-effectiveness.

Stranded cables are more flexible and make excellent patch cords for equipment connections and cross-connects where cables are frequently bent and manipulated. These cables are suitable if we need long-term flexibility and specific motion-based applications.

Choose Solid or Stranded Wires based on Their Properties, Application and other Consideration

Solid wires and stranded wires play a pivotal role in our everyday applications. The selection of these wires requires an understanding of wire properties, application, and other considerations. Gloster Cables is a wire and cable manufacturer that brings quality solid and stranded wires to meet various industrial and domestic applications. Gloster’s expertise in power cables ensures the optimum quality and performance of manufactured solid and stranded wires for different applications.

CONTACT US