Flexible Cables-Addressing the Continuous Changing Needs of Customers

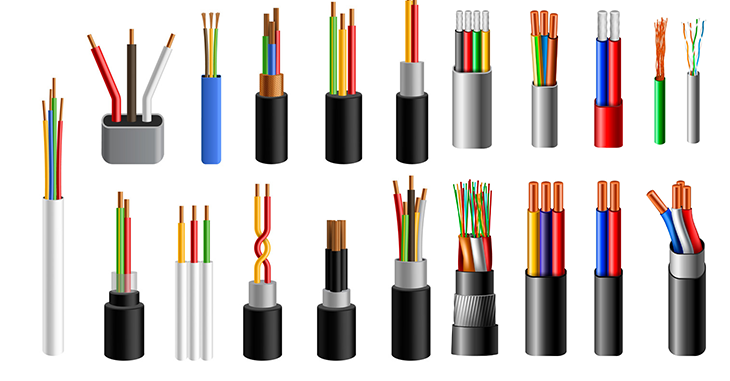

Various situations offer challenges due to cable positioning and gesticulation. Flexible cables are the solution for such conditions where we require continuous bending.

Flexible cables get specially designed to provide superfluous flexibility and longevity. They come in different forms and categories, and we need to carefully select flexible cables to meet our specific application and requirement. The flexible cable specification must match the requirement and specifications to give the desired result.

Introduction to Flexible Cables and Properties that Make Cables Flexible

Flexible cables, also known as continuous-flex cables, are electrical cables that can handle tight bending radii and physical stress during moving applications like inside cable carriers. Highly flexible cables have excellent flexibility, good bending, stretch resistance, and shielding function.

Compared to ordinary cables, flexible cables conductor is different, have different insulation material, and the way of cable formation also differs. They use extruded tubes and extruded sheaths. The conductor diameter of flexible cables is small compared to ordinary cables. And flex cables insulation material has harnesses, flexibility, and strength.

Properties that Make Cables Flexible

Types of Flexible Cables Based on their Construction

We can divide flexible cables into two types based on construction: Conductors stranded in layers inside the cable and braided or bundled conductors inside cables.

Stranding in Layers

Stranding in Layers

Stranding in layers is easy to produce and less expensive. The cable cores get stranded firmly and long in several layers around the center and then enclosed in an extruded tube-shaped jacket. In shielded cables, the cores get wrapped with fleece or foils.ing process, the inner radius compresses, and the outer radius stretches as the cable core moves. Initially, it works well till the material elasticity is sufficient, but gradually material fatigue can set in and cause permanent deformations.

Stranding in Bundles

Stranding in Bundles

It is a unique cable construction technique that braids conductors around a tension-proof center instead of layering them. Avoiding multi-layers gives a uniform bend radius across each conductor, and when the cable flexes, the path of any core moves quickly from inside to outside of the cable. A pressure-filled jacket is preferable for preventing the cores from untwisting an outer jacket. It fills all the gussets around the cores, ensuring cores cannot untwist.

Application Based Flexibles Cables

Here is the list of the most standard flexible cable types and their applications for different purposes.

Non-Motion Rated

Some non-motion-rated cables recommended based on their application are stationary and stationary for routing.

Stationary

Cables rated for stationary motion are mostly rigid and get used in static applications. We use these cables in stationary trays, audio, and studio broadcast system, instrumentation system, and more. These cables should not be routed around corners during installation and do not require bending and flexing.

Stationary- For Routing

If a cable lays static during its application and is routed through machinery or within cable trays with corners or curves, it needs a degree of cable flexibility during installation. For such applications, we need cables rated for flexible applications. Several times because of cable stiffness, it does not get properly routed during installation.

Motion Rated

The motion-rated cables include flexible cables, continuous flex cables, and torsional flex cables.

Flexible

Flexible cables are appropriate, usually in applications where one end of the cable is stationary, and the other end keeps moving. In such applications, where cables do not move, these cables get used for cable tray routing, portable power equipment, wind and solar energy, oil and gas applications, and more.

These cables are often not tested to withstand any number of flex cycles. Therefore, we need to check the manufacturer’s flex cycle testing information, as manufacturers consider different factors when calling a cable flexible, continuous flex, etc.

Continuous Flex

Applications of continuous flex cables range from rolling flex applications like cable track installations to bending flex applications where the cable continuously moves but more variably or randomly. These applications are mostly not automated.

These cables get tested for use between 1 and 20 million flex cycles. We should check the manufacturer’s testing conditions, such as moving robotics, continuously moving gantries, etc. The use of cable should consider factors like motion classification, cycle life range, movement type description, and motion level, making it easy to identify what type of cable suits a specific need.

Torsional Flex

Cables rated for torsional flexing constantly move and twist around an axis and can get pulled back and forth combined with bending and rolling motions. Depending on the manufacturer, torsional flexing cables get tested between 2 and 14 million cycles.

The application of these cables is for robotic pick and place and where a cable will rotate 360 degrees around an axis. It involves repetitive movement through a fixed range of motions for the cable’s life cycle duration.

Reasons Customers Prefer Flexible Cables

Flexible cables need a smart engineering process and quality material to get the desired properties that make them preferable for a few applications. Customers look for flexible cables because of the following reasons.

Increased Service Life

A high level of flexibility increases the service life of a cable inside a cable carrier. An ordinary cable may manage 50000 cycles, but a flex cable may compete for between one and three million cycles.

Sufficient Elasticity

A high level of flexibility increases the service life of a cable inside a cable carrier. An ordinary cable may manage 50000 cycles, but a flex cable may compete for between one and three million cycles.

Sufficient Elasticity

The inner radius gets compressed, and the outer radius stretches during the cable bending process. But due to sufficient elasticity, the flexible copper wire works properly. Own zones of elasticity help in cable stretching and compressing activities. The performance deformations set in only when the material gets fatigued.

Uniform Bend Radius Around Each Conductor

The construction techniques involving the conductor around the center which is tension-proof, guarantee a radius of uniform bends across each conductor. The path of cores can move from inside to outside quickly from one end to another.

Space Efficiency

The cables can fit closely to each other and can use the unutilized space. The overall laying down cost of the cable reduces, as no-dead space is available.

Fire and Heat Retardant

Flexible wires are fire and heat-resistant. In various electrical applications, the temperature may rise during the operation, and fire-retardant properties help them sustain the heat. Fire resistance properties help helps them prevent any mishap.

Light Weight

These cables require minimum material to perform efficiently, and the cross-section reduces to the needed amount to make compact cables size. Thus, the weight of flex wires reduces when we put them in use.

Gloster Cables brings one of the Best Performing Flexible Cables

Gloster Cables, a well-known name in the wire and cable manufacturing field, bring a range of flexible cables. The flexible cables manufactured at Gloster can fit various applications required by customers. Gloster’s flexible cables are fire retardant and fire resistant, lightweight, have sufficient elasticity, and possess other properties that make them best performing in various operational conditions.

CONTACT US