Select Right Load Cell Cables for High-Precision Sensitivity

Load cell, an electro-mechanical sensor, has applications throughout many industries. Scales are the most common application, from kitchen to industrial, conveyor-belt, and bench scales. Other uses include marine, aerospace, construction, and many more.

Load cell cables require specific cables for power transmission from load cells to the indicator. Load cell cables are an integral part of building a custom scale and channel both power and communication in a load cell system. These cables come in various shapes, sizes, and types to meet several industrial and environmental requirements.

What is a Load Cell and its Use?

A load cell is a transducer, converting the mechanical force into readable units, like our regular weighing scales. It converts forces such as tension, compression, pressure, or torque into an electrical signal that gets measured and standardized. As the force to the load cell increases, the electrical signal changes proportionally. The main purpose of a load cell is to weigh or check the amount of load transferred.

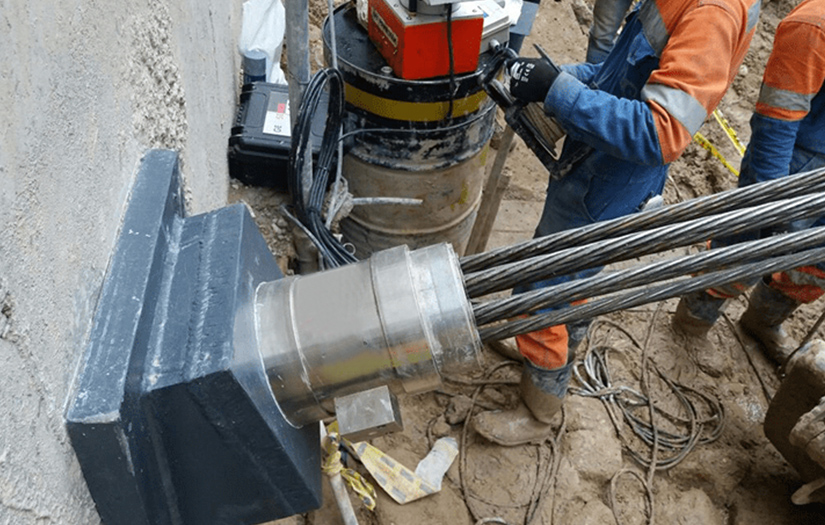

Load cells are available in different shapes, sizes, and types. A few common types of load cells are pneumatic, hydraulic, and stain gauges. Load cells get widely used in the geotechnical field depending on the scope of work. Geotechnical instrumentation encompasses sensors for structural health monitoring, landslide monitoring, excavation monitoring, etc.

In the geotechnical field, load cells are in use for

Excavation bracing, like struts and soldier piles, tiebacks or anchors, retaining walls, and other deep foundation.

Tunnels and shafts: Steel liner plates, cast-in-place concrete, segmented precast concrete, shotcrete, etc.

Concrete dams and powerhouse

Pile load test

We can use load cells at the initial stage of construction, i.e., during the research and development, and even at a later stage while monitoring a structure.

Reasons to have Dedicated Load Cell Cables

We need to electrically connect load cells such that the output signal lines, excitation (power supply), and sense lines are in parallel. Load cells require a cable to transmit the output signal from the load cell transmitter to the display or controller. They need an excitation voltage to produce an output signal. Load cell's output-signal changes with excitation voltage variation. A higher excitation voltage produces a higher output voltage swing when load applies to the cell.

A dedicated load cell cable for a system must offer low resistance. When force or tension applies to a load cell, there is a slight change in the resistance of the load cell's bridge circuit. The load cell transmitter converts the output from the load cell to an extremely low voltage, so the resistance of the load cell cable must have a low influence.

Even small changes in milli volts get transmitted and are susceptible to external voltage influence. Therefore, to maintain the accuracy of the load cell measurement, we need to ensure, correct screening gets used on the cable.

Types of Load Cell Cables, their Specifications, and Application

Load cell cables are available in different types based on distance and environmental conditions.

Types of Load Cell Cables based on Number of Wires

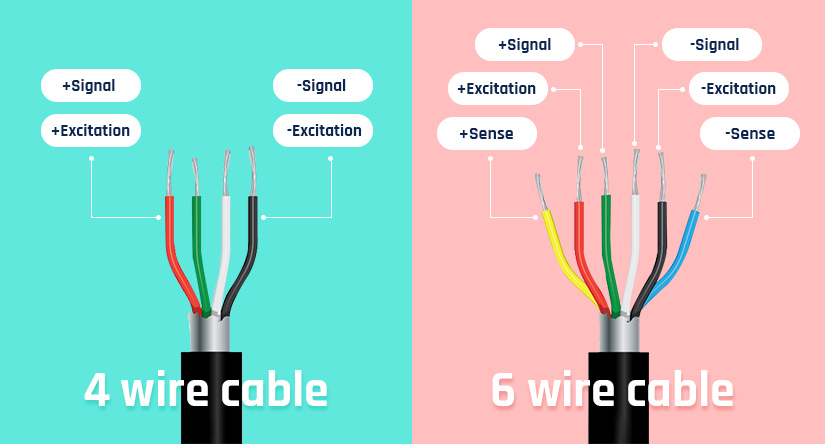

The most common type of cables available are 4-wire cable and 6-wire cable.

4-Wire Load Cell Cable

4-wire cable consists of four wires: Power(excitation) +, Power -, Signal (Output) +, Signal-. The excitation wire delivers a current between 5 to 10 volts to the strain gauge, a resistor type in the load cell. As the resistance changes due to the deformation of mass placed on the load cell, the output typically between o and 30 millivolts transmits through the signal wires. Then, the indicator converts the signal to display weight.

4-wire cables, typically used for short distances, from the scale base or junction box to the indicator. The resistance of a load cell cable varies with length and ambient temperature, and resistance increases with cable length and temperature. Thus, 4-wire cables are thicker and help to contain the voltage drop over longer wire spans. These cables are calibrated and designed to handle the surrounding temperature.

6-Wire Load Cell Cable

6-wire cables consist of six wires, power+, power-, signal +, signal-, sense+ and sense-. These cables are used for long distances and face changes in resistance, temperature, and dips in voltage. The additional sense wires help to factor in resistance change and subsequent voltage drop. They allow the indicator to adjust the output voltage drop with an amplifier to compensate for voltage drops over long distances or varying temperatures.

6-wire cables have no temperature-compensating system, and we can adjust the length of these wires without compromising the cable or re-calibrating the entire system.

Types of Load Cell Cables based on Shielding

The load cell cables get shielded based on the different surrounding environments. The type of load cell cable shielding is as follows.

Standard Cable

Standard cables have foil tape shielding, a braided tinned copper shield, and PVC jacketing for insulation and wire protection. These cables are applicable in controlled environments or as a replacement for existing- damaged factory wire.

Intrinsically Safe Cable

Intrinsically safe cables use industry-standard blue double jackets for cable protection from flammable gases or liquids and other hazardous materials. These cables can perform in explosive environments such as gunpowder, fuel, paint, and other flammable products.

Hostile Environment Cable

These cables are like stranded wires but have an-additional polyurethane jacket rapping around the PVC jacket. They can work in extreme environments, and polyurethane jacketing protects them against many chemicals, including fuels, salts, ether, and other flammable products.

Rodent Protection Cable

Rodent protection cable has a braided shield as the outermost layer of the cable, with a chemical coating that leaves a bad taste in the mouth of rodents. These cables are safe against pesky rats and mice from gnawing and damaging the lengths of wire.

High-Temperature Cable

High-temperature cables have FEP (fluorinated ethylene propylene) jacketing to insulate the wires. They can withstand temperature fluctuation or extreme temperatures without getting damaged.

Benefits of Selecting Right Load Cell Cables

The selection of an appropriate load cell is significant for the proper functioning of a load cell weighing system. The selection of the right load cell cable depends on the distance between two parts of the load cell system, ease of installation, and environmental conditions like temperature, flammable materials, abrasion, rodents, etc.

A few benefits of selecting an appropriate load cell cable are as follows.

In cases where multiple load cells are employed, 6-wire cables are preferable. They can repair sections without re-calibrating the system, run long lengths of the wire and adjust temperature changes in an uncontrolled environment.

An appropriate load cell cable offers the required resistance for a correct reading and minimal influence when a load cell transmitter converts the output signal to an extremely low number of millivolts.

Load cell cables with copper braid and foil with the correct coverage and protection amount to sustain in extreme external conditions.

Load cell cables with PVC insulation can operate to a temperature range of 90 degrees Celsius and PTFE insulation up to 260 degrees Celsius.

Custom design load cables have UV-resistant outer sheath, excellent durability, water resistance, RFI and EMI protection, armored, etc.

Gloster Cables brings Top Quality Load Cell Cable to Meet Various Requirement

Gloster Cables is a leading wire and cable manufacturer, providing wires and cables for several industrial, commercial, and residential applications for the last 25 years. The organization manufactures load cell cables, meeting various quality and industry standards for several industrial applications. Select an appropriate 4-wire load cell cable or 6-wire cable with different shielding for high-load cell precision sensitivity and meet specific environmental conditions and requirements.

CONTACT US