Significance of RTD Cables for Resistance Temperature Detectors

Resistance temperature detectors (RTD) are devices made of platinum used for measuring temperature and used across industries to perform the task of temperature detection. RTD wires connect to the temperature recording or process control instrumentation, and RTD cables help send resistance signals back to the recording, readout, or control device

The application of RTD Cables is in automotive engines, amplifiers, aerospace, communication systems, and more. These cables come in various designs and specifications and offer excellent sensitivity and stability.

What are Resistance Temperature Detectors and Reasons to Use RTDs

A resistance temperature detector (RTD) is a sensor that changes its resistance with the temperature change. RTD’s resistance increases as the sensor temperature increases. This relation between resistance and temperature is repeatable over time.

RTD is a passive device as it does not produce an output. External electronic devices support measuring the resistance of the sensors by passing a small electrical current through the sensor to generate a voltage. The electrical current used is 1 mA or less measuring current, and 5 mA maximum without the risk of self-heating.

Reasons to Use RTD For Various Industrial Applications

The various reasons to use RTD for industrial applications are as follows.

High accuracy

High accuracy

RTD sensors have higher accuracy than thermocouples and thermistors over a wide temperature range.

Stable in application

Stable in application

The application stability of RTD allows it to measure temperature with precision for a given time length.

Offer repeatability

Offer repeatability

Repeatability characteristics of RTD sensors allow them to keep the same physical behavior for any given temperature, even when exposed to different temperatures.

Significance of RTD Cables and Their Standard Specification

RTD cables gets designed to measure temperature. It carries the temperature measurement output where the thermocouple wire can transfer and generate a temperature output. As there is an increase in temperature, the metal’s resistance to electric flow increases. These cables are in use for temperatures up to 1,200° F.

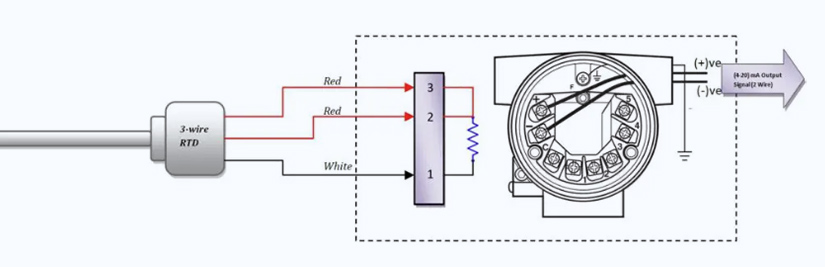

RTD wires connect to the temperature recording or process control instrumentation using copper instrumentation cables, and RTD cables help send resistance signal back to the recording, readout, or control device.

Standard Specification of RTD Cables

Range

Range

RTD cables are available in three wires, four wires, or simplex. They are also available in six or eight wires for duplex RTD.

Conductor Type

Conductor Type

The conductor materials used for RTD cables are electrolytic grade bare copper, tinned copper, SPC, and NPC.

Screened/Unscreened

Screened/Unscreened

The screening is silver-plated copper wire braid, SS over metal braid, aluminum foil type, or mesh braided.

Insulation Material

Insulation Material

The core insulation material is PTFE, FEP, Silicon, PFA, PVC, PE, XLPE, and LSZH Polymer.

Number of Strands

Number of Strands

The conductor strands in RTD cables are solid or multi-strand.

Outer Sheath

Outer Sheath

The outer sheath is fused PTFE tape, Fiberglass insulated, or silicone rubber extruded.

Different Types of RTD Cable Extension

RTD extension wires help connect RTD wires easily, carrying signals from the sensor to the working device while maintaining high accuracy. RTD extension cables should match the material used in producing the positive and negative legs of RTD cables.

Here is a list of RTD extension cables.

Pt100 RTD Extension Cable

Pt100 RTD extension cable extends the length of PT100 sensors, enabling them to operate for long distances. It is made with a PVC insulator, giving it a suitable temperature rating and allowing it to be wipeable.

2 Core Red and 1 White Core RTD Extension Cable

2 Core Red and 1 White Core RTD Extension Cable

These cables have annealed bare copper conductors, PTFE core insulation, and outer jacketing. The outer braiding is stainless-steel wire with white. They have high chemical strength, thermal stability, mechanical strength, outstanding insulation properties, and excellent heat resistance.

RTD Multi conductor Thermocouple Cable

RTD Multi conductor Thermocouple Cable

A thermocouple consists of two wires of dissimilar metals welded into a junction. At the other end of the signal wire is another junction-the reference junction. The heating sensing junction generates thermoelectric potential proportional to the temperature difference between the two junctions.

RTD PT100 Nickel Pleated Copper Extension Cables

RTD PT100 Nickel Pleated Copper Extension Cables

These cables have conductors made of nickel-plated copper, tinned copper, or silver. The insulation material is PFA, and the sheath material- tinned copper, nickel-plated copper, or SUS304.

6 Cores RTD PFA Insulated Cables

6 Cores RTD PFA Insulated Cables

These cables are suitable for use with platinum-resistance thermometers and nickel-resistance thermometers. Each conductor of the RTD cable is PFA-insulated and sheathed.

RTD Cables for Thermistor Signal Leads

RTD Cables for Thermistor Signal Leads

RTD cables for thermistor signal leads have insulation of high-temperature glass, PFA, and Polyvinyl wire. They are available in 2, 3, or 4 conductors.

RTD Type K Cables

RTD Type K Cables

RTD Type K cables have copper/constantan conductor material. The temperature range of these cables is 450 degrees Celsius. It has excellent chemical resistance, dielectric constant, high-temperature stability, high thermal endurance, moisture, and chemical abrasion resistance.

Application of RTD Wires/ Cables

RTD wires and cables are in use for various industrial purposes. Some of them are for

RTD Sensors and Extension Wires

RTD cables are in application as extension wires to transmit signals from RTD sensors to the control unit.

RTD Autoclave

RTD Autoclave sensors can withstand the high pressure and temperature environment of the sterilization process in autoclaves. RTD cables help measure temperature.

Medical Instruments and Scientific Equipment

RTD cables can transmit signals from the sensor to various medical devices and scientific equipment.

Sensors, Load Cells, and Pressure Transducers

Sensors, load cells, and pressure transducers use RTD cables as extension wires to transfer electrical signals from sensors to control units. Pressure transducers is a sensor that converts pressure into electrical signal.

Resistance Thermometer Extension

RTD cables such as Glass fiber braided RTD 6 core cables are suitable for connecting Resistance thermometer assemblies. They offer great mechanical strength, suited for extending out of an assembly connection head for use in connecting to junction boxes.

Process Instrumentation

RTD cable can carry the RTD signal to the control room or field-mounted instrumentation.

Gloster Cable: A RTD Cable Manufacturer

Gloster Cables is a leading wire and cable manufacturer, catering wire and cable needs across the globe for more than 25 years. With its progressive advancement in infrastructure capabilities and market reach, the industry manufactures a wide range of cable and wire products. Gloster designs RTD cables for various industrial applications, such as automotive engines, communication systems, amplifiers, electronics, aerospace, food handling, etc. Gloster RTD cables are of top quality with utmost stability and sensitivity.

CONTACT US