Elevator Cable-The Driving Component of an Elevator

The elevator cable is the crucial component supporting the working mechanism of an elevator. Elevator cables are the multi-conductor wires that connect the elevator car to the controller. These cables are in motion and have exceptional strength and performance.

Elevator cables are available in flat and round shapes that withstand high mechanical stress. Their manufacturing requires high-quality material, PVC insulation, and sheathing, making them suitable for adverse weather and harsh environments.

What is an Elevator Cable and its Features

The elevator cable is an important connection that links the elevator and the controller. In traditional elevators, these traveling cables carry power and signal data. Elevator cables get specific designs to withstand a high amount of mechanical stress. They are more versatile and efficient as compared to the hydraulic ones. This cable sheathing is a special-protective rubber that can remain soft even at minus 15 degrees Celsius.

Some of the main features of Elevator cables are as follows.

Elevator cables are multi-conductor wires with an average life expectancy of 15-20 Years.

These cables have exceptional strength and performance.

Elevator cables are easy to use and handle, and installations are simple.

These cables are PVC insulated, which makes them suitable for adverse weather conditions and safe to use.

Elevator cables are available in various sizes and custom packaging.

Design of an Elevator Cable

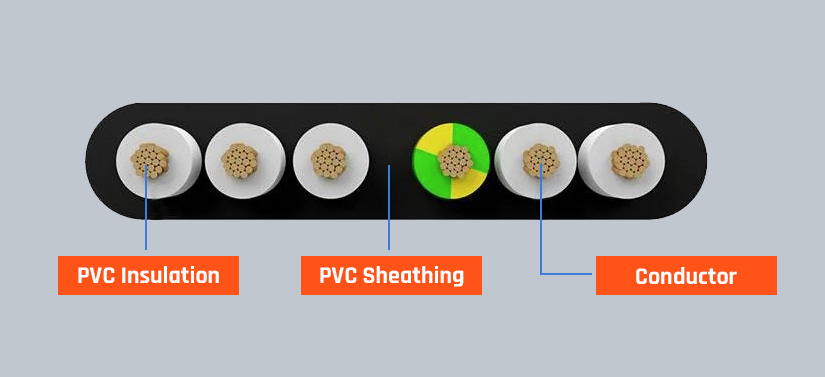

The design of an elevator cable includes a conductor, insulation, and sheathing.

Conductor

Conductor

The cables use bare copper conductors that possess 100% conductivity. The corrosion- resistant property of copper gives elevator cables a longer shelf life. The copper used for a conductor is bare copper, extra fine wire, and highly flexible. Cables' current-carrying capacity increases due to copper. Customized for The Gloster Cables and subject to change by Content Inception. The conductor standard should conform to VDE0295 CLASS 5 standards, and the elevator cable should be made multi-strand super-slender and finally calibrated oxygen-free steel wire. Elevator cable design should put as little strain on the copper as possible, extending the cable life. These wires have white cores with black numbering and a single green or yellow earthing core for easy identification.

Insulation

Insulation

Elevator cables are PVC-insulated and can withstand various chemicals, acids, oils, and alkalis. PVC insulation makes these wires abrasion-resistant and exceptionally sturdy. It makes the cable heat-resistant and reduces smoke emissions.

Sheathing

Sheathing

The outer sheathing is of special plastic PVC that is flexible at low temperatures. The sheathing material should meet the standard Type TM2: EN 50363-4-1 or Type ST5: IEC 60227-1, and the sheath color should be black.

Classification of Elevator Cables Based on their Speed and Size

Elevators cables are available in various categories based on their shape and speed.

Cables Based on Shape

Elevator cables come in round and flat shapes.

Round Elevator Cable

Round Elevator Cable

Round elevator cable contains multistranded oxygen-free copper wire with strong flexibility. The insulation is with environmentally friendly PVC mate. These cables are resistant to oil, water, corrosion, and high and low temperatures. They have high mechanical strength, excellent chemical stability, and dielectric properties. We can use round cables in an environment of -10 degrees Celsius to 70 degrees Celsius temperature.

Flat Elevator Cable

Flat Elevator Cable

Flexible flat elevator cables rated 1Kv and below are Customized for The Gloster Cables and subject to change by Content Inception. applicable in very harsh environments. These cables use Copper conductors of class 5 and class 6, and tinned and plain. The number of cores varies from 2 to 48. The insulation and sheath are of different materials, such as PVC, NBR, TPU, and TPE. These cables have different working temperatures based on insulation and sheathing material. The maximum conducting temperature for PVC insulation and sheathing is 70 degrees Celsius, NBR-70 degrees Celsius, TPE-90 degrees Celsius, and TPU-180 degrees Celsius.

CAT6 Flat Elevator Cable

CAT6 Flat Elevator Cable

CAT6 Flat elevator cable is the unique cable that allows for CCTV monitoring in elevators. The

cable has uninterruptible performance, high signal power, and signal-to-noise ratio.

Cat6 elevator cables have 100% pure copper wire, 4 pairs of 10-38 twisted cores, and PVC

material sheathing. These cables exceed Category 6 and Class E specs.

Cables Based on Speed

Elevators cables classified on speed are

Low Speed Elevator Cable

Low Speed Elevator Cable

Low-speed elevator cable should conform to GB/T 5023.6 and IEC 60227-6 standards. The operating temperature of these cables is between -15℃ to +70℃. They have a copper conductor with PVC insulation and PVC sheathing, and they have a rated voltage of 300V 500V.

Medium and High-Speed Elevator Cable

Medium and High-Speed Elevator Cable

Medium and high-speed elevator cables should meet GB/T 5023.6 and IEC 60227-6 standards. These cables are strong against bends. These cables use copper conductors, PVC insulation sheathing, and copper or tinned copper shielding. These cables have a voltage-withstand test of 2000V/5Min.

High-Speed Elevator Cable

High-Speed Elevator Cable

These cables have a bending resistance for running speed of less than or equal to 10m/s, traveling height of less than or equal to 300m, loop diameter of less than 1100mm, and operating temperature -15℃ to +70℃. Similar to low-speed and medium-speed cables, high- speed cables use copper conductors, PVC insulation sheathing, and copper or tinned copper shielding.

Benefits of Using Elevator Cables

Here is a list of benefits of using flat and round elevator cables.

Meets the Demand of Small Thin Wires

Meets the Demand of Small Thin Wires

Today’s market demand for slim and thin wires and flat elevator cables is a practical solution for this rising demand. These cables have low torque attributes and long life and are ideal for scenarios that require undetectable circuitry.

Flexibility

Flexibility

Flat elevator cables have a smaller bend radius than round cables, as conductors are placed parallel in a flat plane. These cables are super flexible and can withstand 15 million flex cycles. Flat cables are a better alternative for situations with tiny bend radii and heavy flex cycles. We can use these cables for applications involving motion, for example, robots and axis control manufacturing equipment.

Electrical Properties

Electrical Properties

Elevator cables have consistent electrical properties such as impedance, capacitance, inductance, time delay, cross talk, and attenuation. Conductor spacing and cable geometry of elevator cables make these electrical properties consistent.

Reduced Time Delay Between Signals

Reduced Time Delay Between Signals

Flat cable conductors have the exact physical and electrical length and a continuous and consistent dielectric. It reduces the time delays between signals within a given flat cable.

A Better Performing Elevators Cable Defines an Elevator Function

Most elevators function through an elevator cable, and the higher the cable performance, the better the elevator's function. Gloster Cable, a leading wire and cable manufacturing firm, manufactures elevator cables customized to the needs of its clients. Gloster elevator cables are made under expert supervision and follow stringent quality tests to meet national and international standards.

CONTACT US