Cable Shielding - An Effective Way to Combat Electromagnetic Interference

Industrial or manufacturing unit working under a controlled environment prefers unshielded cable application. These working environments are protected from ambient electromagnetic interference (EMI) as the metals of the enclosure shield the electronics inside.

The demand for shielded cables rises in industrial units, frequently under the influence of EMI. Unshielded cables don't suit environments where a large amount of power is used or needed, as they create a large amount of EMI. Shielding reduces interference and helps maintain signal integrity. Metallic braids and foil shielding are popular wire and cable shielding options to counter EMI.

EMI and the Importance of Shielding Over Insulation in Countering EMI

Industries and their factory floor operate in an electrically noisy environment. These electrical noises radiated or conducted as Electromagnetic interference can disrupt equipment operation.

Heavy processing steel mills, foundries, and plants have high noise sources, like electrolytic processes, heavy motors, generators, transformers, induction heating, relay controls, power lines, and control wires nearby. Average manufacturing plants operate under medium-level noise due to wiring near medium-sized motors and control relays. Storage areas, labs, offices, and light assembly operations generate low noise levels, such as wiring far from power lines, motors, no induction heating, etc.

Cable as the Main Source of Transfer of EMI

Cables can be the primary source of EMI transfer, both as a source and receiver. The cables acting as a source- can conduct noise to other equipment or function as an antenna radiating noise. And as the receiver can pick up EMI radiated from various sources. Switching heavy loads, inductive heaters, and large transformers can all present a high level of both conducted and radiated EMI.

How Cable Shielding Combats EMI in Cables

Cable insulation helps protect a cable mechanically by avoiding scraps and abrasion. Insulated cables are resistant to environmental moisture and spills. However, insulated cables are transparent to electromagnetic energy as they are not EMI-protected. Therefore, shielding is needed to combat the effects of EMI.Shielding surrounds the power-carrying conductor or inner signal, acting on EMI in two ways. First, it reflects the energy and second-picks up the noise and conducts it to the ground. In both conditions, EMI does not reach the conductor. However, few energies still pass through the shield. But it is highly attenuated, causing no interference.

Shielded Cables and Types of Shielding

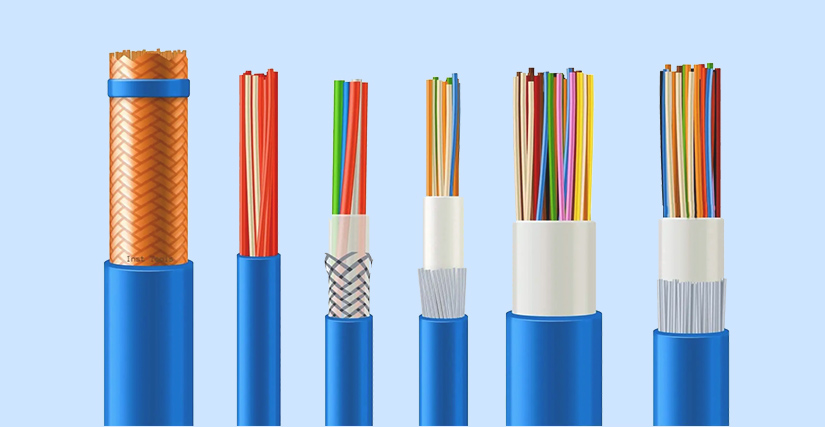

Cables are available with various degrees of shielding, giving different degrees of cable effectiveness. The amount of cable shielding depends on factors like electrical environment, protection level, physical considerations-cable diameter, weight, flexibility, and cable cost.

Types of Shielding

Primarily, two types of shielding are in application for cables-Foil Shield and Braid shield. However, there are additional shielding options available that suit different applications.

Foil Shields

Foil Shields

The materials used for constructing foil shields are aluminum and mylar composite tape. The foil shield is lightweight, inexpensive, and easy to apply. It provides 100 percent shield coverage and gets terminated with a drain wire. Foil provides good flexibility but limited flex-life.

We should consider certain factors while using foil shields, such as thin and light weight, good flexibility, mediocre flex life, easy termination, little physical protection, and no mechanical strength. These shields are less costly than braids, and we can combine braids with foil to maximize performance.

Metallic Braid Shields

Metallic Braid Shields

A braid is a woven mesh of bare or tinned copper wires. It provides a low-resistance path to the ground and is much easier for termination by crimping or soldering when attaching a connector.

Braided shields do not provide 100 percent coverage. They allow small gaps. And based on weave tightness, provide 70% to 95% coverage.

As copper has more conductivity than aluminum, braid has more bulk for conducting noise and is more effective as a shield. But it adds size and cost to the cable. In contrast to foil shields- the braid shields offer physical protection, increased mechanical strength, and are difficult to terminate.

Spiral/Serve Shields

Spiral/Serve Shields

Spiral or serve shields use bare, tinned, or silver-plated copper strands for formation. And steel and other metals help in physical protection. These shields are more flexible than braid shields and provide easy termination.

A spiral shield is constructed by wrapping the shield material in one direction around the conductors and wrapping the shield material in both directions on separate layers with no interweaving of wires, helping form a reverse spiral. These cables are suitable for audio applications due to the frequencies they can shield against.

Tape Shields

Tape Shields

Tape shield uses materials like copper, aluminum, and bronze. Copper and aluminum combined with a backing such as mylar or polyester, like a foil shield. They can reach a coverage of 100%, and the properties are similar to foil shields.

Combination Shields

Combination Shields

Combination shields use two or more shields in the same cable, such as a braid shield over a foil shield or a braid shield over a braid shield. They provide maximum shield effectiveness, good physical protection, easy termination, good flexibility, 100% coverage, good flex life, and mechanical strength. They have low DC resistance and a high cost of production.

Application of Shielded Cables in Various Environments

Shielded wires and cables can benefit any industry or industrial process that uses equipment radiating or conducting EMI. Some major applications of shielded cable include

Industrial and Manufacturing Factories

Unshielded cables used in industrial units can lead to equipment downtime, measurement errors, errors in data communication, and many more. By using shielded cables, they can protect their people and processes.

Data Centres

Data centers house a large number of electronic devices transmitting many signals. It may lead to decreased equipment performance. Therefore, integrating EMI shielding in cables is crucial for them.

Medical Facilities

Many medical facilities address EMI issues by banning mobiles. Properly shielding the wires and cables in equipment prevents the effect of EMI on device performance.

Offices

Shielded wires and cables are essential in offices with heavy computers and other electrical/electronic equipment. It addresses EMI issues and increases equipment performance.

Military Sites

Electronic devices and systems such as missiles, portable communication systems, electronic warfare systems, ground vehicles, avionics, etc., serve a crucial function in military sites. Shielded wires and cables ensure their safe operation and effectiveness.

Gloster Cables - An Experienced Shielded Wires and Cables Provider

Gloster Cables is a well-known wire and cable manufacturer with around 25 years of experience providing wire and cable solutions. The industry manufactures various shielded wires and cables to meet the needs of several domain industries. Gloster custom shielding solutions can help meet your specific application requirements.

CONTACT US