| 1.1 KV grade AL/CU conductor PVC and XLPE insulated armoured / unarmoured cable 2,3, 3.5 & 4 core | BIS 1554 (P-1) 1988 BIS 7098 (P-1) 1988 |

| 1.1 KV grade PVC / XLPE insulated AL wire/strip armoured – 1 core up to 1000 sqmm | |

| 1.1 KV grade PVC / XLPE insulated Copper conductor control cable | |

| 3.3 to 33 KV (E) grade cable from 25 to 500 sq.mm cable Aluminium / Copper conductor, Screened, GI round/formed wire armoured cable | BIS 7098 (P-II) 2011 |

| 1.1 KV Single core 0.5 to 6 sq.mm TRIPLE EXTRUSION FRLSH wire AND ZHFR wire for domestic wiring application | BIS 694’2010 |

| 1.1 KV Single core 10 to 630 sq.mm Flexible cable copper conductor | |

| 1.1 KV grade Copper flexible conductor PVC insulated multicore cable for industrial application. | |

| 1.1 KV grade Copper flexible for submersible pump application | |

| 1.1 KV Aerial Bunched Cable 35 sq.mm to 185 sq.mm | BIS 14255 |

| HT 11KV Arial Bunched Cable 35 sq.mm to 185 sq.mm | ≠≠BIS 7098 (P-2) |

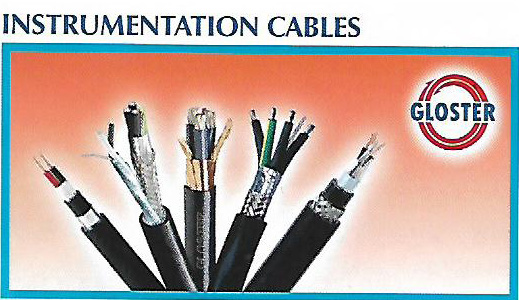

Instrumentation cables including RTD cables

Fire alarm Cable (armoured / unarmoured) |

BS-5308: Part 1 & 2, BS EN 50288/7 |

| 500/1100 Volts Fire Survival Cables | BS 7846 / BS 6387 |

| Solar cable for Photovoltaic system | EN50618 -2014 |

FIRE SURVIVAL CABLE

Gloster is guided by the maxim “Safety is not expensive. It is priceless”. We therefore manufacture the safest Fire Survival cables in the Indian market

> Gloster FS cables can offer the following features

Gloster FS cables can offer the following features

- Fire resistance

- Limited circuit integrity in a fire

- Low smoke and toxic gas emissions

- Flame retardant properties

- Zero halogen gases

- Ease and low cost of installation

Gloster Cables Ltd Manufacture Cables that maintain circuit integrity under fire conditions for

a certain limited time. These cables are also popularly known as FS cables (Fire Survival

Cable) or FR Cable (Fire Resistant Cables), if the fire persists for sufficient duration, as all

the plastic components such as insulation, sheathing would all get charred, but however

the circuit integrity of the cable will remain for a limited period of time.

Purpose

FS cables are meant to ensure that the cables used in emergency loads such as emergency lighting [sign boards], emergency ventilation, Pressurization fans, etc. keep working during a fire situation in a building, so that the occupants who are trapped in the building are able to

- See the exit signs which are still lit even under fire and are able to get guided out of the building safely

- Are able to breathe properly due to the working of the smoke extraction fans even under fire

- Are able to use the staircase areas, due to the pressurization fans working

- Also, the water pumps are working to ensure the water is sprayed at the required locations for quenching the fire.

Some of the suggested Applications areas are as below

Fire resistant safety circuits, Public address and emergency voice communication systems, Control and instrumentation systems and High-temperature installation conditions, buildings such as

- High Rise Buildings, Residential & Commercial Complex

- Cinema Theatres

- Metro rail & Railway Tunnels

- Airport

- Hospitals, School & College

- Shopping Malls

- Basement areas, Underground car parking

- Atriums

- Electrically operated fire shutters and smoke curtains

- Military Installations

Basic product details

These cables are able to maintain their circuit integrity even under fire for a defined time as per standards, because of a fire barrier placed over each conductor, preventing the conductors touching each other and getting shorted even in the event of complete insulation burning. The fire barrier usually consists of mica tape[s], which handle high temperatures.

Gloster uses only muscovite MICA tape which can handle up to 1000ᴼC without any problems. These are costlier than phlogopite MICA tape which is a lot cheaper, but has a limited flame temperature handling of up to 800ᴼC only. In addition, for armoured cables

Gloster uses an additional fire barrier below the armour for additional safety to protect against the heat generated from the metal particle i.e. armour Cable construction usually as follow:

Conductor : Bare or Tinned copper solid, stranded or flexible type

Fire Barrier : Layers of Glass Mica Tape

Insulation : Heat Resistant PVC, XLPE with additional taping or screening if required

Inner sheath : Fire resistant PVC, FRLS PVC, Low smoke zero halogen

Armour : Galvanized steel wire or strip

Outer sheath : Fire resistant PVC, Flame Retardant Low smoke PVC, LHLS or ZHLS compound

Special construction is also offered application dependent or on requirement.

Some of the fire testing standards like category C of BS 6387 specify testing at 950 ᴼC up to 3 hours. Test method are usually followed as per Standard BS 6387, BS 8491, BS 8434-2, BS EN 50200 and IEC 60331.

Instrumentation cables are multiple conductor cables that convey low energy electrical signals used for monitoring or controlling electrical power systems and their associated processes. The functions of measurement and control are vital in manufacturing and processing applications.

Multicore unscreened / pair / overall screened cables are also manufactured as per

BS:5308-I & II: PAS/ BS EN -50288/7 and also as per customer's requirements

Polyethylene / PVC insulated instrumentation cables are offered as per BS:5308-I/ & 2 : 2009: PAS as per customer's requirements or as per various National / International

standards such as IEC, BS, VDE, IS, etc. can be supplied by us.

Conductor material shall be annealed bare copper or annealed tinned copper as required.

Insulation / sheathing material used is PVC, HR-PVC and Polyethylene as per customer's requirement.

Shielding material shall be as per customer's requirement. Some types of shielding materials used are given below:

a) Aluminium Mylar tape screening along with drain wire of ATC.

b) Copper tape screening accompanied by drain wire of ATC.

c) ABC / ATC wire braiding

Laid up cores shall be unarmoured or armoured with galvanized round steel wire or strip as per customer’s requirement.

Depending on application and environment, Cables can also be supplied with Flame retardant(FR) or Flame Retardant Low Smoke(FRLS) or Low Smoke Zero Halogen(LSZH) sheathing compounds as per customer’s requirement.

Solar Cables

Solar photovoltaic cables are used for transmitting electrical power generated from the solar

panel to the charging units, battery banks, change over systems, inverters etc. The cables

that are used to carry power from the solar panels to the charging units have to function

effectively while remaining exposed to a wide range of severe environmental conditions.

Solar Cables are designed to meet the growing needs of the solar industry. Our solar cables

is just the beginning of our plans to develop and launch green technology in wires & cables.

Solar Cables are flexible and are resistant to abrasion & moisture. Regardless of your panel-

to-grid needs, we have the cables to meet your requirements.

Standards

As per EN 50618:2014.

Electrical Characteristics

- Rated Voltage: 1.0/1.0 kV AC

- Rated DC Voltage: 1.5 kV

- Maximum Permitted DC Voltage: 1.8 kV

- Maximum Permitted AC Voltage: 1.2 kV

- Voltage Withstand: 6500 V as per EN50395 for 5 min

| Conductor | Electrolytic grade, annealed tinned copper flexible conductor as per EN/ IEC 60228, Class 5. |

| Insulation | Cross linked & fulfils the requirement as specified in Table B.1 in Annexure B of EN 50618’2014. |

| Sheath | Cross linked & fulfils the requirement as specified in Table B.1. |

Thermal Characteristics

- UV Resistant

- Ambient temperature (-40)ᴼC to (+90ᴼC) lower operating temperature on request

- Maximum Temperature at Conductor: 120°C (20000h)

- Short Circuit Temperature: 250°C for 5 sec max

- Thermal Endurance Test: According to EN 60216-1 & 2 (temperature index +120°C)

- Damp – Heat Test: According to EN 60068-2-78 1000 hrs. at 90°C with 85% humidity

Mechanical Characteristics

- Minimum Bending Radius: 5 x OD (fixed), 15 x OD (occasional flexing)

- Dynamic Penetration: According to requirement of Cables for PV systems.

- Tensile Strength: 8 N/mm2 for insulation and 8 N/mm2 for sheathing – according to EN60811.

- Anticipated Period of Use: 25 years (as per standard) and 37.7 years (estimated by the testing laboratory after completion of long duration thermal endurance tests as per EN 50618:2014).

- Shrinkage: as per EN60811.

Characteristics

- Ozone Resistance: according to EN 60811

- Weathering-UV Resistance: according to EN 50618:2014 Annex E.

- Acid & Alkaline Resistance: According to EN 60811.

Fire Performance

- Flame retardant according to IEC 60332-1-2

- Low smoke emission of complete cable as per EN 61034-2

- Halogen free according to EN 50525-1

Domestic Wire segment –

While introducing this product, aspect of SAFETY has been our prime consideration. Thus, Gloster has been the first Company in India having introduced TRIPLE EXTRUSION

TECHNOLOGY with FRLSH properties (HR-FRLSH + FRLSH + FRLSH) with additional features as below. Our theme “Safety is not expensive – It is priceless”.

Conductor higher than 99.97% pure bright electrolytic grade copper with Class 5 for better flexibility and laid in unilay profile.

grade copper with Class 5 for better flexibility and laid in unilay profile.

Specially formulated in-house HR-FRLSH insulation in 1 st layer – withstand more rise of

conductor temperature while on load. As against 70ᴼC rise of temperature of conventional

insulation, ours withstand beyond 70ᴼC continuous and 105ᴼC peak due to HR-FRLSH

compound.

Specially formulated in-house thick FRLSH insulation in 2 nd layer – restricts spread of flames,

creation of poisonous smoke, toxic & corrosive gases – eliminate panic, asphyxiation, life

threat and destruction of expensive electronic goods and house hold properties.

3 rd layer is abrasion resistant with insulation dielectric remains intact and strong.

FRLSH characteristics like oxygen index, temperature index, smoke density, Halogen %,

flammability etc. are strictly ensured as per applicable BIS and ASTM/IEC National and

international standards.

State-of-the-art Triple extrusion technology – ensures excellent bonding between all three layers.

Products in Pipeline

- PTFE [Teflon] Cables

- Rubber Cables

- Reeling / Unreeling applications

- Mining applications

- Welding Cables

- Elevator Cables

- Battery Leads

- High Mast Lighting

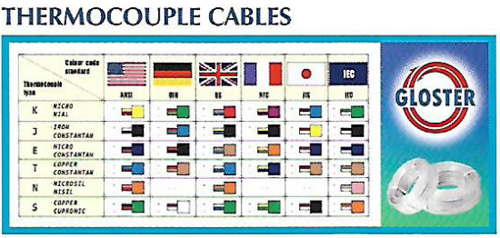

- Thermocouple Cables

- Load Cell Cables

- Cables for VFD application

- Cables for Cathode Protection

- Coaxial Cables - RG6/RG11/RG59

- Other Special Cables