Gloster Cables: A name for Quality, Safety, and Innovation

Wires and cables for the power system are as crucial as our blood vessels for the human system. The significance of wires and cables is everywhere around us.

Acting as the transmission medium for the power system, information system, mechanical instrumentation system, wires/cables serve us in many ways.

Cables are the lifeline of a system, whether industrial, commercial, or residential, and the operational efficiency of these systems highly depends on cable's durability and signal integrity. To ensure the reliability of wires and cables performance, we need to consider the constraints such as mechanical, electrical, chemical, operational, and other environmental factors that can stress the cable system and its various applications.

Gloster cables are a well-established name in the wires and cables industry, catering to various domestic and industrial electrical needs for the last two decades. Gloster follows a meticulous process to manufacture cables inclusive of market research, technology, innovation, and international and national safety standards.

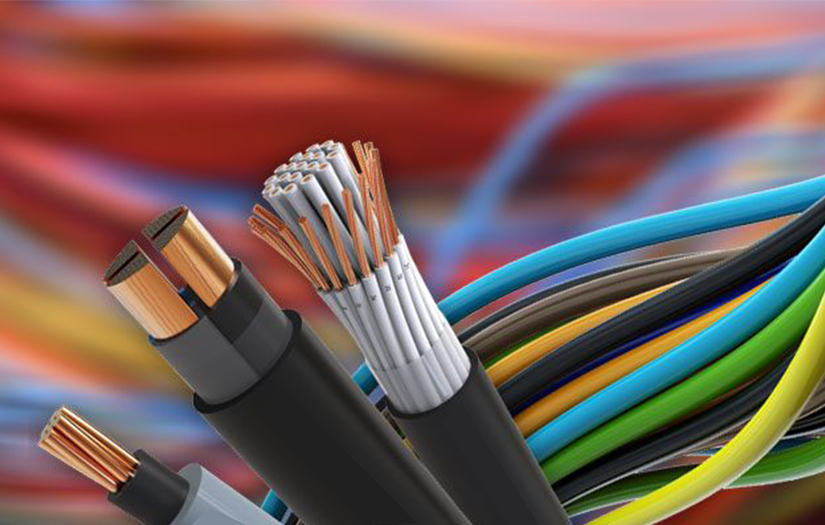

Gloster’s product spectrum serving different purposes and sectors

The advancement in technology, industrialization & urbanization has compelled the wires and cables industry for innovative products. And even meet wire/cables demands for different purposes.

Gloster provides a vast range of innovative products catering to several industries. Such as manufacturing, power transmission, construction, automotive, IT and telecom, etc. These wires and cables are designed for high electric transmission and even endure industrial stress due to harsh operational, mechanical, environmental conditions, and other factory hazards. They have sheathings like PUR, PUR A, PVC, PVC A, POC, and others to increase their mechanical, thermal, and environmental strength.

Some of our industrial-grade wires include

We cater to commercial and residential segments with innovative and special-purpose products. The list of our commercial and domestic grade wires and cables are not limited to

In addition to these, Gloster has added special cables with U/L certification like instrumentation cables, railway signaling cables, and Solar Cables in its portfolio.

Intent to Develop Useful Cables/Wires Products

The wires and Cables industry has to face technological changes and the demand for innovative, high-quality products with resistivity towards environmental, thermal, chemical, electrical, mechanical, and several other operational challenges encountered at their place of usage.

At Gloster, we conduct research and development on core technologies in the cable industry such as conductor design, extreme fire resistance, masking technology, compounds for high-performance cables, optimal conductor design, insulation, braided sheaths, etc.

The research on processing technology helps develop a total solution for metallic materials and alloys for cable conductors. Our research on materials and insulation materials supports enhancing the credibility of cables, developing eco-friendly cable compounds, and high insulation.

Gloster sources raw materials from reliable and reputed manufacturers. For quality testing of these materials, we use NABL calibrated testing equipment as per Indian and International standards.

Some international standards that we follow for our quality testing are IS: 1554 for PVC Cables, IS: 7098 for XLPE & XIPE cables, IS: 14255 for AB cables, IS 694 for housing cables, and BS 7846, BS7629, and BS 6387 for fire survival cables.

Manufacturing Process Leading to High-Quality Products

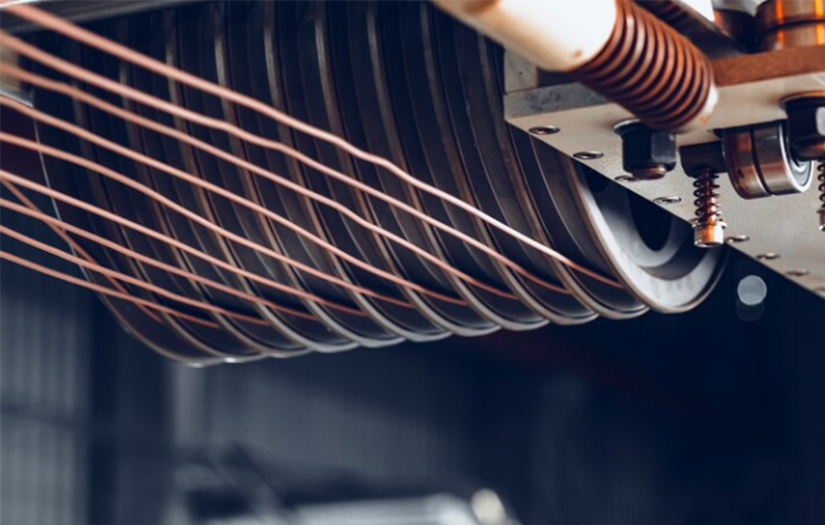

The wires and cables get processed for specific purposes and applications; therefore, their manufacturing process is complex and tedious. The basic manufacturing process and steps that we follow are drawing, wire annealing, twisting & stranding, hot extrusion, voltage testing, phase wiring, and additional protection.

Wire Drawing

It gets softened, flows, or distorts when exposed to sufficient heat and pressure. These compounds are heated and extruded over the conductor. The insulation on the finished product can be re-melted or softened if exposed to heat.

Annealing

IFor improving the physical properties of wire, its ductility, and conductivity, we give heat treatment through annealing. Annealing is done in two stages, batch annealing and strand annealing.

Twisting & Stranding

After heat treatment, wires with the same cross-sectional area are twisted or stranded using a proprietary formula that helps identify the twist length. The electrical performance and flexibility of the conductor improve with this process.

Hot Extrusion

The wire passes through an extruder to apply plastic coating or insulation. It depends on the wiring requirement, thermal resistance, and capacity.

Voltage testing, Phase wiring, and Cabling

TVoltage testing helps identify any current leakage of fault in insulation. The multi-core wires are colored and numbered to differentiate different phases.

After phase wiring, we assemble the cables in cable stations, such as the electrical cable wrapped with a protective jacket or an interference preventing layer. We give a round shape using fillers. Our buried underground cables have several layers like inner sheath, armour, and outer sheath.

Some manufacturing process standards that we follow at Gloster are fine drawing machines for online annealing, high-speed extruders, rigid QC process, and automatic diameter control.

Gloster ZHFR cables are insulated up to 16 sq. mm for better insulation and high electrical properties.

Gloster’s Motto is Safety Above All

The motto of Gloster is safety above all and maintaining the safety level of its products. Our stringent Quality policy with adherence to national and international standards ensures the safety of the products.

Gloster is an ISO 9001:2008 certified organization following international standards such as DNV, BS, and IEC. Each manufactured product at Gloster goes through rigorous quality checks and gets certificated by independent quality certification agencies such as NABL, CPRI, and ERDA.

We have the latest testing instruments and get a specialized test facility per the latest standards. Such as, we perform oxygen and temperature index test with automatic control, smoke density tests with recorder and printer, acid gas generation test following international standards, and perform all fire tests for FS cables.

The raw materials used by Gloster give the wires and cables durability, ensuring safety and quality.

Promotes electrical safety in domestic and commercial establishments

With urbanization and an increase in the number of high-rise residential buildings and complex commercial establishments, fire safety has become one of the major concerns.

Gloster helps tackle such challenges with its wide range of fire-resistant and fire-retardant cables. These cables slow down the spread of fire and increase the chances of escape and survival.

Our fire-resistant cables have limited circuit integrity, enabling them to perform even during a fire. The cable insulation and jacketing emit low smoke and gas because of the used material.

Flame retardant cables reduce the spread of fire, whereas halogen-free cables do not produce any toxic halogen gases ensuring the safety of homes and commercial units.

Why US?

Gloster cable is a reliable and trustworthy brand in the business of wires and cables.

The company has been manufacturing high-quality, durable, and innovative wires/cables for the industrial, commercial, and domestic sectors since 1995.

The adherence to ISO, BS, IEC, and other international standards compels it to bring the safest and optimum quality products.

The team at Gloster continuously put its effort into market research and even understand the requirement and consequently develop innovative products to meet the demand. Our priority to safety gives us an edge above our competitors and is one of the best choices in the wires and cables industry.

CONTACT US